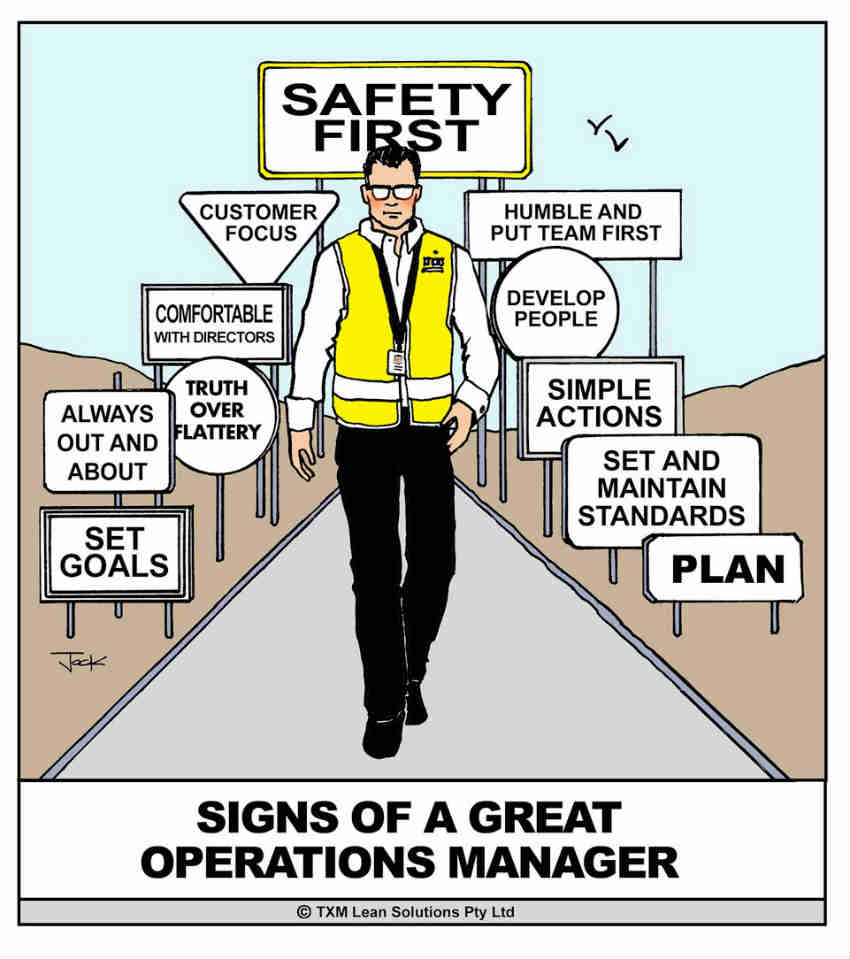

What Makes a Great Operations Manager?

In last month’s blog I talked about the problem of excessive senior management turnover. I also gave you some pointers about some warning signs that perhaps your manager is not working out. Since then, my business partner, Anthony Clyne has rightly pointed out that I need to share some thoughts on what are the positive characteristics and behaviours of a good Operations Manager.

The challenge is that some of these seem counter-intuitive and you might not recognise them as positive behaviours, or worse, see them as negatives.

So what are the signs that you have hired a really effective Operations Manager or General Manager in your business?

They Prioritise Safety First and Then the Customer

As an Operations Manager, they have very direct responsibility for the safety of the people who work in your business.

This responsibility translates to you as the business owner, CEO or Director as well. Therefore, the first thing a new Operations Manager is likely to do is to identify, assess and address any immediate safety issues.

This also demonstrates their commitment to their team. It provides them a chance to demonstrate that they are committed to the standards they set – so production never comes before safety.

Next to safety, an Operations Manager should recognise that any business must always meet the needs of its customers. This means that the Operations Manager will address quality and delivery issues, before leaping in to cost-cutting. It also means that an Operations Manager will use positive language about the customer. They will be curious to learn what customers really need and value from the product or service the business provides.

They are Humble and Put the Team First

Often, we look for Operations Managers who are bold, tough, confident and decisive. These characteristics can be useful, but in my experience, the best and most successful Operations Managers constantly give the limelight to their team. When talking about the projects and achievements of their area, they will use “we” and “us” more than “I”.

In presentations, they may often let their team present and take a back seat themselves. They will also stand up for their team and support them, even at some cost to themselves. However, they will be decisive, fair and consistent in managing the performance of the individuals on their team. They will value the experience around them and look to develop the people they have before turning over key roles.

However, they will also be prepared to challenge complacency and entrenched views. This may include challenging some of your long-serving subject matter experts. If you want to learn more, pick up a copy of “Good to Great”, by Jim Collins and read about “Level 5 leadership”. The TED Talk “Why Good Leaders Make You Feel Safe” by Simon Sinek is also a great explanation of what good leaders do.

An Operations Manager who displays these traits will earn the respect of their team rather than expect it. This earned respect is typically rewarded with the team confidently following the direction the Operations Manager set and makes the team more at ease with deviating from “the way we’ve always done it”.

Because they are humble, they good leaders admit what they don’t know and ask for help when they need it. This should not be seen as a sign of weakness, but in fact, is a sign of strength. It takes strength to reveal one’s weaknesses and vulnerabilities and ask for help. Rather than criticising or rejecting such requests, you should welcome them and try and provide the help and resources needed.

They will also be respectful of others in the business. Behaviour like swearing, shouting or belittling staff have no place in the workplace under any circumstances, especially from leaders.

They will Develop People and Won’t Feel Threatened by Peers and Subordinates

In fact, they will actively develop their senior team members and provide them opportunities, including allowing them to step up in to the Operations Manager role during holidays and travel. They will be comfortable allowing their team to make decisions and take full responsibility for aspects of the business.

They will support their team, even when their decisions go wrong (they will never throw a team member “under the bus”). However, they will ensure that their team also takes accountability for the decisions they make and the responsibilities they take on.

They will work hard to develop peer relationships and invite feedback and involvement of peers. They won’t gossip about peers or criticise peers (especially to their team). They also will not tolerate “them and us” attitudes in their team that can erode relationships between functions and impact customer service.

When Things go Wrong, They Ask Why Not Who

A good Operations Manager is not going to spend hours whining to you about their subordinates or their peers. Their focus will be on the process, not the individual. When things go wrong they will ask why and seek to find and address the root cause of problems.

This can be difficult and time-consuming at the start, when there are many problems (its much quicker just to blame someone!), but it in the medium term it is an investment of time you must make if your business to sustainably improve performance.

They Set, Maintain and Improve Standards.

Excellent performance is achieved from establishing well thought out standard processes and then continually improving these processes.

An effective Operations Manager will, therefore, focus early in their role on establishing standard processes and ways of doing things. This can include standardising the organisation of the workplace with 5S, standardising key tasks with standardised work, standardising business processes in the key business value streams and establishing formal or informal service level agreements (SLAs) with the functions with which operations interact (e.g. sales and purchasing). In doing so, they highlight the importance and required level of respect between internal suppliers and customers.

Having set the standard, the effective Operations Manager will work to maintain the standard. They know that the “standard they walk by is the standard they accept” and so they will never “walk by” something that is not to standard without taking action.

They will also expect you to comply with these standards as well. Therefore, if you have got into the habit of walking in the workplace without personal protective equipment or not observing 5S standards, expect to be told to comply – and make sure you do!

Sometimes this focus on standards can seem like bureaucracy and slowing things down and you are allowed to ask “why” things are being done a certain way.

The effective Operations Manager will be comfortable with having their processes challenged and be able to explain why the standard needs to be followed or work with their team to improve the standard. However, they will always expect that there is a standard and that it is followed.

They are Well Organised

Operations Managers often have to juggle a broad range of responsibilities. Therefore it is important that the person in that role is well organised. You should see this in a well-organised desk and office that shows signs of some kind of a system to manage daily activities and projects.

Ideally, the Operations Manager will have a system of regular routines or leader standard work. These will be written down and tracked. You should be able to get some evidence of this being followed such as a tee card board or checklist.

Beyond themselves, they will also expect their team to be well organised. Therefore expect them to get their team members to develop their own plans and their own lists of daily routine tasks.

They Have a Plan with Clear Simple Actions and Goals

When your new Operations Manager starts, one of their first priorities will be to understand the business strategy and the role of operations in delivering that strategy.

They will develop a plan for operations to support the strategy while seeking your input and the input of the team along the way. They will quickly identify the few critical metrics that drive operational performance and set challenging but realistic targets for these.

These goals and the plan will be systematically communicated throughout the operations team so that every team member in operations knows their individual or team objectives and how they can contribute to improved performance.

Importantly they will focus on the simple things first, getting the basics right before they start introducing more complex changes. They quickly identify one or two key metrics that drive operational performance in the business and focus on improving those rather than introducing a huge range of metrics.

Ideally, they will reinforce the plan and the objectives every day with a Lean Daily Leadership Process that provides feedback to their team and seeks their input on problems every day. This structure of short daily meetings will cascade up the organisation. They may encourage you to lead a regular stand up meeting or conference call at senior management level to help set the overall business direction and address high-level problems.

They Don’t Substitute Money for Brains

Many Operations Managers are engineers. Engineers love technology (that’s often why they became engineers!) and get excited about robots and fancy data acquisition software.

However, a good Operations Manager, will not be constantly presenting you with shopping lists of capital investments and software tools. Instead, they will focus on trying to get the most out of the assets and tools they have.

When they do come to you with a request for capital it will be supported by a strong business case, will be well thought out and will align with the operations plan and business strategy.

You Won’t Find Them In Their Office Very Often

The Operations Manager role is often the lynchpin of a manufacturing or distribution business. They typically have the most staff reporting to them and the greatest number of interactions with peers. Therefore, a good Operations Manager will spend a lot of their time out and about.

You might find them out in the workplace, interacting with their team and observing the process on a workplace walk. They could be meeting with peers, running a daily standup meeting or having an on-site meeting with suppliers or customers. They will generally be on site (beware of the Operations Manager who always finds a reason to be out of the business), but even when they are in their office they will be rarely alone.

Despite this, they may allow themselves a bit of solitary reflection time during the day to catch up on issues and plan future actions. This is often at the start of the day, around lunchtime or at the end of the day. If you see this, avoid getting in the habit of “just dropping in for a chat” at these times, but instead schedule regular structured catch-ups in their office.

Another mistake to avoid is over-loading your Operations Manager with transactional work. They are the key leader in your business and the person who will drive improvement in your business. They are also, typically, a fairly expensive resource.

Therefore, tying them to their computer doing purchase orders, production schedules or stock adjustments is a waste of their resource and will prevent them doing their job effectively. Get a clerical staff member on half an Operations Manager’s salary to do the transactional work and focus the Operations Manager on leading their team and driving improvement.

They Tell You the Truth – Not Just What You Want to Hear

It is nice to be told how great you are and how right you are. We all have an ego and are all susceptible to flattery. However, a good Operations Manager will be prepared to give you challenging, considered constructive feedback and you need to be prepared to take it.

You also need to be prepared for the fact that not every idea you have will be regarded as a good one. The Operations Manager should be comfortable with your presence in the business and on the shop floor, but it is best that these shop floor walks occur with the Operations Manager, at least at the start.

Avoid the temptation to establish a “back channel” of communication with long term employees as this will strongly undermine your Operations Manager and make these long term employees believe that they are “untouchable” because they have a “direct line to the boss”.

Conclusion

There are many other attributes of a good Operations Manager, but if your new person is demonstrating most or all of the operations management skills I have listed above, even if short term performance is not where you would like it to be, then it will pay to stick with them.