Office Process Design

Once a burning platform or case for change has been established within a company the step change for office processes begins. We start by using lean principles to understand the current situation for the office processes, then develop a future state plan to meet our goal. The implementation plan addresses how we close the gap between the two situations. Often it is easy to get lost amongst the details of the people we have and their current skill set. Here we will look at how to develop a process and determining WHAT value-added tasks are needed to support the future state plans, then look at how we determine WHO we get to do these tasks. Developing a robust implementation plan, including the checking and auditing, will help us be successful in implementing our change and meet our goal.

Determining WHAT with Value Stream Mapping

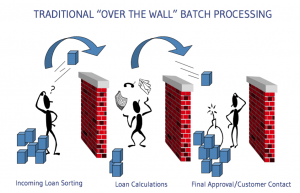

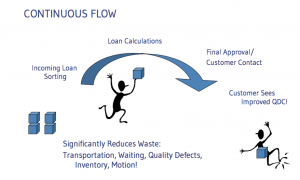

The Lean Value Stream Mapping approach allows us to visualise our current process and information steps. As we work through the TXM 8 Steps on Developing a Future State, tasks are reviewed with the aim of creating flow and removing the wastes in the process. We determine if the process steps are needed at all or if they can be combined with other tasks; this instantly begins to focus on flow by reducing the waiting and queue times between process steps and departments. Here we want to be clear on WHAT tasks are needed to complete the process steps and add value to our product or service, from the customer perspective.

Sometimes we get caught up in the detail of who currently does the tasks and how busy they are; a good facilitator will help to guide these concerns and focus back onto the tasks first. After we have a clear picture to WHAT needs doing, then we can consider who does them, and how.

Determining WHO with Process Design

Once we have determined WHAT tasks need doing, we can turn our attention towards WHO does these tasks. Firstly let’s understand what skills are needed to complete each task most efficiently; is it an understanding of our MRP system? Or our accounting system? Or technical knowledge of our products? List the skills needed to complete the tasks, then consider who is the best person or people to complete these tasks.

Often in a big company, having one person completing the new process will not provide enough capacity to meet the company’s needs. As we outline how big that task is we can consider if we need more than one person to complete the tasks concurrently. So rather than taking a step backward and breaking the process into several parts, with handovers between people, consider utilising the gains of flow by having one person complete the task from start to finish, and duplicate this new process as the capacity is required. This lets us complete many jobs across the entire process at the same time. And it will improve the efficiency of the process as the queuing and waiting are removed.

Developing the Implementation Plan

Just determining what and who for our new step changed process isn’t enough; now there real hard work start with documenting, training, checking our improvements have been successful and coaching to close any gaps found.

Documentation

As much as possible we like to utilise the company’s existing documentation process for standard or SOPs. If you don’t have any, it is simple enough to create a visual document with a flow chart of the key steps and some words to make sure we have done our best to explain how the new process will work.

We also need to document how the process will be controlled and instigated; this may be done by reviewing daily or weekly, so we can check on how we went in the last review period and look at what is needed in the next day or week.

Training

now the draft documentation is ready to go, we can begin to train everyone in the new process. It is important that everyone attends the training to make sure we all understand why we are making these changes. We also need to train back up people to help make our process more robust and not reliant on a small number of people. This puts us in a better position when people get sick or have holidays, and reduces the risk of letting the team slide back into the old ways.

The leadership team also needs to have an awareness of the new processes. Clear escalation rules and how to handle interference also need to be considered as we set up a new system for success.

Check and Audit

As the new process is implemented, be clear in how we will check and audit the new processes. This may include:

– the agreed-to cycle time and lead times are being met

– review meetings are being attended

– escalation process works

Coaching

Any gaps that are noted during the auditing may be dressed with coaching. Review the documentation and training, and work with the individual to understand where those gaps are occurring.

Conclusion

When developing a new business process, it’s important to focus on the value-added tasks first – noting WHAT needs to be done – before heading into the details and working on WHO will complete the tasks. Then having a robust implementation plan will help your new process be implemented successfully, and not just another failed change attempt.