Visual Controls in your Workplace

Visual controls are an important part of management in every manufacturing and office workplace allowing a quick recognition of the information being communicated, in order to increase efficiency and clarity. When people come together to complete tasks and add value to your products or services, we need to find ways to clearly and efficiently communicate with each other. Here we will look at why we need visual controls as part of our management strategy, identify the basic types of visual controls and how we can to implement these.

Why We Need Visual Controls

Visual controls allow us to communicate without words and share information without interrupting. It helps to get everyone working together by providing a clear understanding of what is required at that point in time. Visual controls contribute to the management of every process in a way that individuals alone are not able to do, by showing where discrepancies occur. As with many of the lean enterprise principles we need to put systems in place to easily identify when things are going well so don’t need to worry about them. This allows us, and our management team, to easily assess the situation across the factory and know when we need to act when things are not under control or an appropriate response is not being undertaken.

John Shook, in his article “Visual Management – The Good, The Bad and the Ugly” notes “If I can see it, I can fix it.” – Dr. Thoralf Sundt of Mayo Clinic. The reverse must also be true – it’s hard to fix what you can’t see. It is important that everyone in our management, production and support teams are able to see what is going on and to know if it’s good or bad. Implementing visual controls, reviewing them on a regular basis and sustaining them will assist with the managing process.

The lean enterprise principles are being implemented across many different industries. There are many great examples of visual controls and visual management that we can learn from and implement from these other industries into our own workplace.

Basic Types of Visual Controls

With the aim of making sure that we can see the status of any process, part or person, and decide if it is good or bad at a glance, many different two main groups of visual controls; display groups and control groups.

Controls or location controls include lines on the floor, colour coding and shadow boards for a range of processes. They are intended to guide the action of our team. These basic type of visual controls need very little explanation as to what they mean and what action is required. The challenge with these controls is ensuring compliance from everyone in our team. The benefit of course with these types of control is that our brains are hardwired to comply, making the right thing to do being the only thing to do.

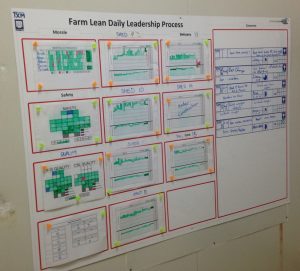

Metrics and charts are display controls which provide information and feedback on the performance of the number of elements. The best examples of these are extremely easy to understand. There is consistency across each chart and across each area within our business, making it easier for people moving across areas to understand the status and knowing how they need to respond.

How to Implement Visual Controls

As we begin to implement our visual management and controls there are several things we need to consider.

Q1 “What do I need to know?”

Q2 “What do I need to share?”

Q3 What questions am I frequently asked?

When we ask these questions we need to consider which hat we’re wearing; if you’re looking at production metrics make sure you are wearing your production team member hat and considering these questions from their perspective. If we’re looking at factory level visual controls we need to encompass a broader group of people being considered how they may answer these questions.

At any lean implementation, we need to approach each element as an experiment. Let’s give two or three visual controls a try in each area. Then we can check how well we have trained communicated their intent to our team and monitor how well they are adhered to. If our controls being ignored and not used, then either we haven’t communicated their intent clearly enough, or we haven’t made them simple enough to become part about everyday tasks.

The challenge is to get the balance correct. Too many visual controls can cause confusion or creative visual overload some elements may be overlooked.

Conclusion

Including visual controls is self-evident; implementing them well so they are adhered to and used to the benefit of the employees and the company as a whole is the challenge. Call a TXM Lean Consultant to guide you with your visual controls implementation.