How Two Businesses Bounced Back with 300% Growth

Around twelve years ago, TXM Lean Solutions was a small emerging Lean consulting company facing the prospect of a global recession. Lehmann Brothers had collapsed, and the global economy was teetering on the brink. We expected that the last thing that clients would want to do is hire a consultant, so we prepared for the worst.

In fact, what occurred is the opposite of what we expected. Some visionary business leaders recognised the Global Financial Crisis (GFC) as an opportunity to take stock and address underlying issues in their businesses to prepare themselves for the opportunities economic recovery will bring. We are seeing signs of the same thing happening as companies emerge from Coronavirus lockdown.

Two companies that approached us in 2009 have proven the strategic value of taking such a positive approach to recovering from a crisis. Both companies were established and successful medium sized family owned businesses in their respective markets. However, both had recognised fundamental gaps between what they promised to customers and what the business actually delivered.

Case Study 1 – Haymes Paint

Haymes Paint was a highly respected third generation family business. Haymes had a reputation for quality and integrity. The business had established a niche servicing independent paint specialist stores, especially in regional areas. These stores were often neglected by the larger paint companies. Unfortunately, the service promise made by Haymes to its independent paint store customers back in 2009 was not matched by reality.

Despite a lot of effort and investment in traditional forecast-driven supply chain management, delivery on time in full was stuck at around 85%. As well, to compete with the bigger producers, Haymes was compelled to produce a full range of products. With less than 5% market share this meant the business had to offer a long “tail” of slow moving items. Restrictions around minimum batch sizes meant that stock for these items often ran into many months, that is if they weren’t out of stock altogether.

Working with TXM, Haymes developed a Lean supply chain from supply of raw materials to delivery of finished goods. Lead times at every step of the process were compressed from weeks to days. This enabled the reliance on forecasts to be reduced and replenishment be driven by what was “pulled” from the marketplace rather than what was “pushed” by the forecast. Batch sizes were slashed – in many cases halved, but innovative Lean systems enabled this to be achieved with no loss of efficiency or overall throughput.

The result was that on time in full delivery was pushed to 95%+ while at the same time reducing inventory by up to one third. This transformation then meant that Haymes could genuinely deliver what it promised to its target customers. This gave the sales team the confidence to convert this message into a growing range of stockists across Australia. Ten years later, thanks to a supply chain and manufacturing that delivers and some excellent marketing and sales efforts, Haymes has more than tripled its revenue.

Profits have increased by even more. The decision to invest in improving business performance in the depths of the GFC paid off handsomely in the recovery and with the foreign purchase of the three largest Australian paint companies, Haymes is now the number one Australian-owned paint brand.

Read our Haymes Paint Case Study

Case Study Two – Hilton Manufacturing

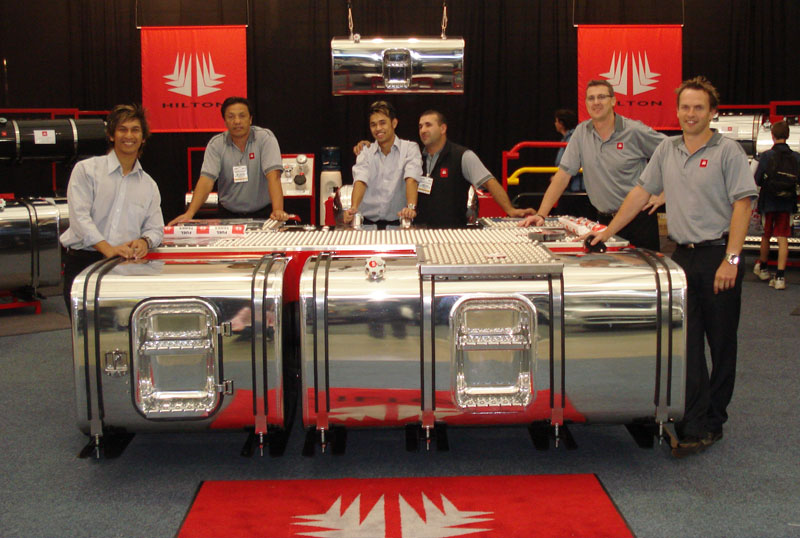

It was a similar story in a very different business at sheet-metal fabricator, Hilton Manufacturing. Lead at the time by father and son team Tom and Todd Hartley, Hilton had developed a leading market position in the custom manufacture of heavy truck fuel tanks and associated components. As well Hilton produced other custom sheet metal components and assemblies for a wide range of customers. In a taste of things to come, Hilton had also taken on outsourced manufacture of nursing home beds for a major healthcare products supplier. A similar sized business to Haymes, Hilton had been hit very hard by the GFC when its customers cut daily build rates by up to 75%. However, like Haymes, Hilton saw this downturn as an opportunity to improve rather than retrench.

Hilton’s largest customers were global heavy truck manufacturers. These businesses operated Lean assembly lines and expected just in time delivery. They could not afford parts to be delivered late. Unfortunately, Hilton’s production system was not aligned with the needs of their customers. Lead times for some components could exceed a month, even though customers were expecting delivery in days. This lead to a huge amount of expediting and waste. As well, even though fuel tank production was highly efficient and responsive, the supply of components to the fuel tank line was anything but. Therefore, tanks could be manufactured in a day or two, but only if all the components were available, which was often not the case.

At Hilton, TXM worked to streamline the end to end flow for custom components, using FIFO lanes to control the backlog of work in progress at each production step. We set up Kanban supply of components to the fuel tank line and extended the “cellular manufacturing” concept used for fuel tanks to other key component cells. The result was that lead times went from around a month down to less than a week, fuel tanks could be reliably supplied in one to two days and work in progress was dramatically reduced, freeing up large amounts of space. More importantly, Hilton’s Lean production system aligned with its customers’ meaning that the business was able to consistently deliver just in time.

This lead to the awarding of more contracts for more key truck components including pressed radiator grilles, air cleaner ducts and wide range of others. As well the “outsourced production” model has grown with Hilton now manufacturing complete products on behalf of a number of companies. It has used its lean expertise to set up these new product lines as Lean “cells” right from the start, ensuring they can manufacture competitively, at short lead times and with minimal working capital. Like Haymes, Hilton has tripled its revenue.

Read our Hilton Manufacturing Case Study

The Lesson

When a crisis like the GFC 2008 or COVID-19 hits, the temptation is to “hunker down”. Stop non-essential spending, retrench all but your most essential staff, pause all investment and strategic plans. However, all this achieves is to guarantee that your business will recover slowly and, at best, get back to pre-crisis levels years into the future. That is, unless your competitors don’t “hunker down” and instead lift their game putting you at a disadvantage.

Of course, it is necessary to be a bit conservative and preserve cash in a crisis. There is no point spending a truck load of money on future investment only to go broke in the process. However, as our recent global manufacturing survey showed, most manufacturers are facing a downturn, not a disaster, and will be able to comfortably survive and trade out of the crisis. This slowdown is not great, but it also provides an opportunity, while the business is not so stretched, to make some genuine improvements for the long term.

The smart companies today, like Haymes and Hilton 10 years ago are looking forward and asking themselves how they can be a better business. Over the last month at TXM our phones around the world have been running hot with companies wanting to talk to us about improving their layout, increasing their efficiency, improving on time delivery, optimising their supply chains, reducing their lead times and improving their quality. These businesses are thinking beyond 2020 or even 2021 to position themselves for the next boom – are you?