Maintenance as an Essential Part of Lean Manufacturing

As we implemented and refined our Lean Management System the stability of the processes becomes extremely important. We need a good parts supply, reliable quality, dependable people, with the skills to complete the tasks needed, and of course, machines that we know will work when we need them to run. This article will be looking at why maintenance is an essential part of any Lean Enterprise system and how to get started to include maintenance as a key part of our Lean Enterprise.

Running our equipment until it breaks is not a robust strategy as part of any Lean system. Production needs stability by minimising machine breakdowns and planning preventative maintenance into the production schedule. As with many of our Lean elements doing small tasks on a regular basis provides a much better long-term outcome, as compare to leaving the important tasks until they are vitally urgent.

Regular maintenance needs to be conducted with the operators as well is with the maintenance team because it is the operators who spend a lot of time with the equipment. They are the first line of defence when something goes wrong with the equipment or if production quality begins to vary. We need the operators to identify that there’s a problem and stop running the equipment. This will minimise continuing to produce poor quality parts as well as risking further damage to the expensive machinery.

Lean Tools for Maintenance

Many of the lean tools have a direct application into the maintenance part of our business. At TXM we hope you have been including the maintenance department as part of your lean implementation team. The people that understand the machinery the best are important resources. And this must include both the operators and the maintenance fitters.

Housekeeping and 5S

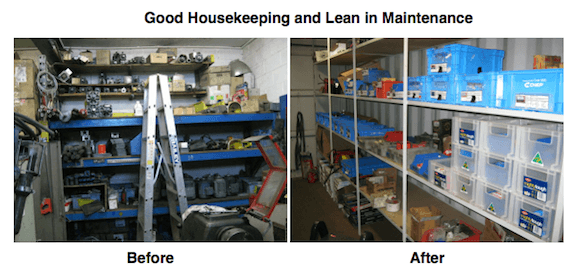

Somehow many Maintenance departments become the dumping ground for every old piece of equipment and machine part that the company has ever owned. The first step in getting Maintenance aligned with the company Lean goals is to have a very good clean up and implement some basic 5S principles. Sort out what is needed. In Maintenance, we want to allow for one-offs and contingencies but you need to be realistic – if you have parts that you know may now be reliable and will most likely order a new part rather than refurbishing the one you are storing, then the old one needs to go – salvage and recycle where possible.

There is no place for a general dumping ground in the Lean Maintenance department. Once the basic sort is complete, find homes for what’s needed and label locations. Do this with input for all of your maintenance team, even (especially) with those on other shifts. There is often a large amount of waste in maintenance departments whee it is just easier to buy new parts rather than find what you already have, so having a good clean up and sort out is an important first step.

Parts Supply

Now that every thing has a location in the Maintenance department, establish a good process for purchasing and replacing parts and stock. A simple kanban or two-bin system will be sufficient for most maintenance departments, for items that are often used. Understanding your equipment and which parts are often needed will help guide you with this process. For expensive items which may not be need to replace regularly you need to consider how much stock to hold. If there is an item that is extremely hard to get you might consider holding it in stock to ensure that Maintenance it is not holding up the production line if something breaks.

Reviewing the history of your equipment is important part of implementing this process. Also refer to the machine manual to understand what daily and weekly checks may be needed and make sure you have the parts to carry out these checks or replacements efficiently.

Standard Work

Once some level of order has been restored and part supplies are working reliably, you need to concentrate on some of the regular tasks that maintenance needs to do in Production. A cross functional team involving the operators, maintenance people and other support areas is a great way to review the requirements for each piece of equipment and develop buy in at the earliest point in rolling out a maintenance process. Using a simple standard form determine what daily, weekly and monthly checks are needed, as well as other major maintenance milestones that may be identified in the equipment manuals. This can all be tied into your Total Preventative Maintenance strategy and you can read more about TPM here.

Conclusion

TXM has had a lot of success with incorporating Lean and Maintenance. With one large national company, over $60,000 in savings were identified by sorting out the Maintenance department and establishing a kanban system. It prevented Maintenance Fitters across three shifts from ordering more parts when they couldn’t find what they needed, as well as reducing inventory by deciding which suppliers could deliver parts within a day.