Lean has evolved over the years becoming the go to methodology for process improvement and continuous improvement.

Visual management is the lifeblood of a Lean production system. It provides insight across teams, departments and management. It is the link between the people and the data. Giving every stakeholder a clear picture of the day-to-day goals and objectives of the business.

We’ve broken down this article into 7 parts which you can jump right into after clicking on the links below:

What is Visual Management?

Visual management is the framework to communicate expectations, performance, standards, and problems in a method that requires little to no time to understand. You may have heard of visual management being used on the factory floor, but it can be used in a variety of industries and environments.

The key to growing a business is often the ability to empower people at every level to make decisions and take accountability. The TXM Lean Daily Leadership Process (LDLP) that our lean consultants use is our proven methodology that brings together visual management and leader standard work to achieve this empowerment.

Lean Manufacturing is a process that emphasizes the elimination of waste in all areas of production. One key component of Lean is visual management, which is the use of visual cues to help workers identify and correct problems in real-time. Common examples of visual management include labelling supplies and work areas, posting rules and procedures, and using colour-coded systems to track progress. By making information more visible, visual management helps Lean manufacturing teams work more efficiently and effectively.

In addition, visual management can also help to improve safety by reducing the chance of human error. As Lean manufacturing continues to grow in popularity, so too does the importance of visual management.

What Do We Mean by Managing Visually?

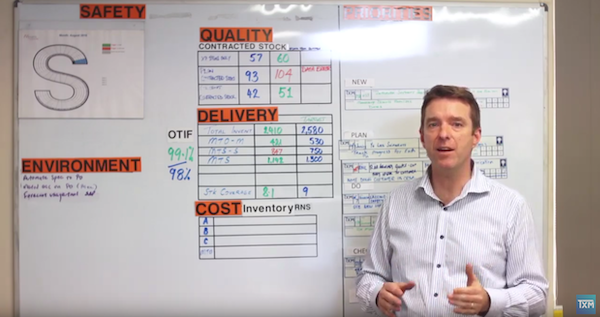

Managing visually is the ability of a system to quickly show the current status to anyone that stands and observes, within 30 seconds. It may be the production status, quality standards, delivery status or a machine status. There are indicators in place to let everyone know how things are tracking.

If visual management has been done well, EVERYONE in your factory understands and knows how to fix an issue if something is wrong.

What is the Focus and Purpose of Visual Management?

Visual management is used to share information, work standards, build on those standards, highlight problems, stop problems occurring and prevent problems altogether.

It is a key component of Lean Manufacturing, which is a production methodology that emphasizes efficiency and quality. The goal of visual management is to make it easy for workers to see what needs to be done, when it needs to be done, and how it needs to be done. This can be accomplished through the use of charts, graphs, and other visual aids. By making information more visible, workers are able to work more efficiently and make fewer mistakes.

Sharing Information

One of the major goals of visual management is the sharing of information.

This information is usually about the day to day operation with metrics showing inputs, outputs, and any problems. This is one of the main purposes of visual management, the ability to share information succinctly.

Developing Standard Work

Visual management also has the ability to build standard work and processes. Improving these standards is the main purpose of Lean and building a culture of continuous improvement.

These standards are then built upon with new and improved processes evolving with the business.

Sharing Standard Work

Another objective is to share standards of how work should be completed. This helps with shift change overs and training staff in the standard work procedures.

Standard work will eliminate waste in the process creating stability and consistency within your Lean Production System.

Highlighting Problems

Another objective of visual management is to highlight problems when they occur, appearing out of the ordinary and deviating from the standard.

Andon Lights can highlight problems on the factory floor in real-time while metrics on the visual management boards highlight problems hourly or daily.

Solving Problems

Highlighting problems and issues on a visual management board allows for the problem to be analysed and worked through at the point of the problem. It can accelerate the problem-solving process driving quick results.

What are the Benefits of Visual Management?

Saving Time

Visual management has the ability to cut down the time it takes to understand and process the information on the board.

An efficient visual management board should communicate the status of the work area within 30 seconds.

Real-Time Updates

Visual management creates a centralised location for all updates to be kept and housed.

It is usually updated daily to provide up-to-date information on production targets, sales targets and problems and issues.

Faster Problem Solving

It provides a structured system to discuss and work through problems in a formal setting, helping users accelerate the problem-solving process.

By using tools like root cause analysis and problem solving strips you can solve the most complex problems faced by business in a timely fashion.

Improved Accountability

Visual management allows for greater accountability for everyone in the process. Helping to define roles, allocate tasks and give a standard work procedure to follow.

Everyone in the process has ownership for their daily tasks.

Improved Team Performance

Improved accountability can translate into higher team performance.

The purpose of visual management is to improve team performance and drive a step-change in efficiency.

Waste Reduction

Completing processes at the right time has an impact on reducing the amount of waste produced.

By giving stakeholders the correct up-to-date information and resources being properly utilised has a dramatic effect on waste reduction.

Types of Visual Management

Visual management is formed by a combination of Visual Metrics and Visual Controls into easily digestible information with little to no training to understand.

Visual Metrics

These are among the first tools implemented when starting Lean implementation.

This is the displaying of data to tell us how each area is tracking. The challenge is to ensure the information is gathered by those doing the work, in a timely fashion, and displayed so everyone in the area understands the current status.

This also needs to be taken a step further; metrics must drive actions and there needs to be a clearly defined process for taking action and getting support when it’s needed.

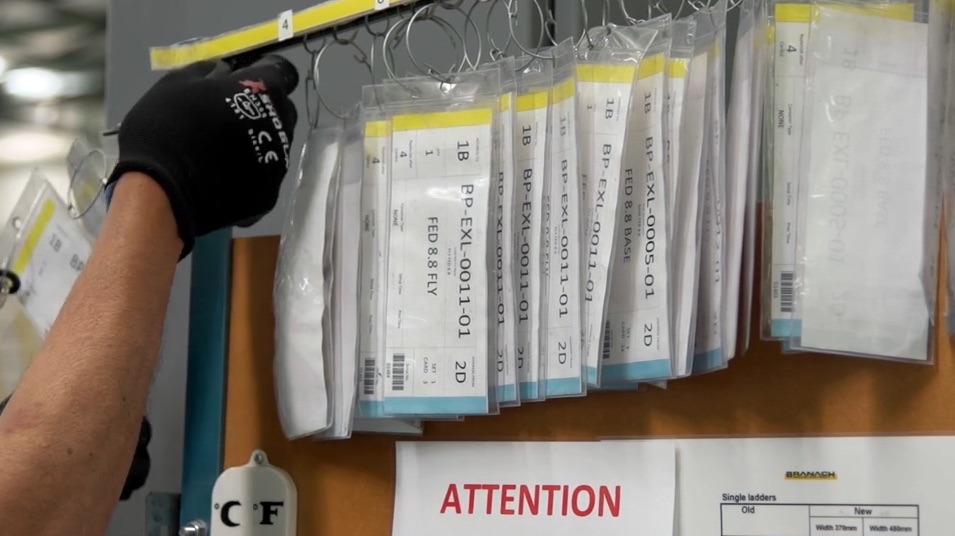

Visual Controls

They cover more broadly how an area works physically – matters of where items are located, general housekeeping and controlling the flow of production can all be covered by using visual control. For visual controls to be effective there needs to be a clearly defined process for getting support when it’s needed.

Visual Management Boards can help you answer questions on the factory floor that might take hours to answer if not done via a Visual Management Board.

- Can you tell how each area is performing?

- Will they meet their targets this week?

- Who is doing something to correct the problem?

- When will it be fixed by?

If you can’t answer these questions within a few minutes, then it’s time to revisit your Visual Management and the data you collect.

Read more about Visual Management Tools and Controls.

Visual Management Examples

Lean manufacturing is a production technique that emphasizes the minimization of waste.

By making information more visible, workers are able to identify problems more quickly and take corrective action more efficiently. As a result, visual management can help Lean manufacturing operations run more smoothly and ultimately improve overall productivity.

Continuous Improvement Boards

Using a simple design and layout these boards are used to display short term actions. These types of boards are usually found on the factory floor with machine status, daily output metrics and problem-solving issues for all employees to see.

Project Status Boards

Status boards are agile project management tools, acting as a focus point where teams can visualise work, limit work in progress and maximise resources. It gives all stakeholders a clear picture and objective for the short and long-term goals of the project.

Daily Management Boards

Probably one of the more used board designs is a daily management board, used to communicate between shifts and across departments. The information displays on this type of board is simple and easy to understand.

5S Control Board

A control provides a central control and tracking of a 5S system. It highlights progress on a 5S audit, tasks to complete as well as clearly showing who is responsible for different areas of the workplace and different activities in the workplace.

5S Visual Management

5S and Visual management go hand in hand being the heart and soul of a Lean production system. 5S workplace organisation is a simple, practical approach delivering sustainability by sorting out, setting in order, shining and checking, standardising and sustaining.

5S uses visuals to achieve its goal of a standardised system used by every stakeholder in the business whether on the factory floor or in the office 5S and visual management can help start your Lean transformation on the right foot.

What are the Principles of Visual Management?

Lean Manufacturing is a philosophy that argues that maximizing value and minimizing waste are the two most important principles in manufacturing. Lean Manufacturing aims to create value for the customer by eliminating waste throughout the manufacturing process. One of the key tools Lean Manufacturers use to achieve these goals is visual management.

Visual management is the practice of using visual aids to communicate information throughout the manufacturing process.

By making information visible, Lean Manufacturers can make the manufacturing process more efficient and ensure that everyone is working towards the same goal. The principles of visual management can be summarized as follows:

- make the situation easily understood merely by looking at it,

- get as much information as possible with as little observation or time as possible,

- and complement well with the idea of going to the real place (Genchi Genbutsu).

When used correctly, visual management can help Lean Manufacturers achieve their goals of creating value for the customer and minimizing waste throughout the manufacturing process.

Need Help Creating a Visual Management Board? Contact Us Now!

Related Articles