Client: Larnec Doors

Location: Swan Hill, Australia

The Challenge

Lean Processes Deliver 80% Reduction in Order Lead Time

Despite its rural location,Larnec Doors had enjoyed healthy growth since its inception but recently came under pressure from low cost Chinese imports. Managing Director Phil Joyce realised that the way to compete was to offer customised doors made to order in the same lead time offered by the ex-stock Chinese product. Having seen a presentation by TXM Coach Tim McLean on the advantages Lean approaches can deliver, Larnec engaged TXM. A Tailored Advisory Service Grant from Enterprise Connect assisted Larnec Doors in implementing the program.

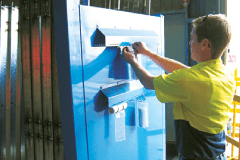

Figure 1 – This kanban system controls daily production in the sheetmetal shop, ensuring that parts do not run out while reducing inventory and eliminating the need for managers and supervisors to spend to day expediting jobs.

THE TXM RESPONSE

TXM started by developing a value stream map of the manufacturing process for Larnec’s two main door lines. The map revealed that the lead time to manufacture a door was between 10 and 12 days, much more than the four days that the business needed to achieve.

With coaching from TXM Consultants, Tim McLean and Anthony Clyne, the Larnec team developed a future state map and action plan for the business outlining the changes needed to achieve its lead time target. The changes were major and Larnec took action quickly.

Working with the TXM consultants, the team developed a new plant layout which involved relocating key machines, creating a natural flow of production from punching to folding to robot welding. Integrating assembly with product packing and despatch freed up a factory building previously used for despatch only and eliminated double handling. A Kanban system was set up to trigger manufacture of door jams in the metal fabrication area and specially designed kit trolleys transport small batches of products through assembly on an hourly basis.

To support the system TXM coached the Larnec team on implementation of 5S to organise the workplace and structured problem solving techniques to discover and correct the root causes of problems on the shop floor.

THE RESULTS

Larnec achieved productivity improvements of up to 50%. The business remains committed to continuous improvement and is now extending its lean production system into the manufacture of wooden doors and their range of Champion Horse stable partitions.

COMMENTS FROM OUR CLIENT

“We get as much more work done in half the time it used to take. Lead time targets have been exceeded with 90% of doors manufactured to order in under four days.”

“Management of the plant is a lot simpler and we no longer need to worry about what is running on the punch or folders – as long as the Kanban cards are moving through the system we know we are on track.”