WHAT IS SIX SIGMA?

Have you ever sat in a meeting and heard the term “Six Sigma,” only to wonder what it truly means?

Is it the latest corporate jargon or something genuinely transformative?

Six Sigma is a methodology that is used to define measure analyze and improve company processes using a disciplined, data-driven approach.

We’ll look at the principles of Six Sigma, methodologies and more…

Six Sigma Definition

Six Sigma originated as a method of improving quality performance from Motorola in the mid 1980’s.

This approach was then adopted by other US companies and broadened to include wider aspects of business through the 1990’s.

Early adopters of Six Sigma included Honeywell, ABB and, most famously, GE, where CEO Jack Welsh drove the introduction of Six Sigma.

Six Sigma Improving Processes

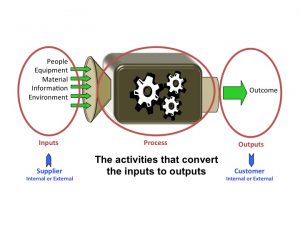

The focus of Six Sigma is on improving business processes by reducing variation. To this end Six Sigma deploys a range of qualitative and quantitative analysis tools to enable businesses to analyse their processes, identify problems, develop solutions, implement these solutions and track the results.

The quantitative analysis tools typically involve use of statistical analysis of various levels sophistication.

Six Sigma Tools For Implementing Principles

These can include simple tools such as Pareto Charts and Histograms, through various types of run charts that track the performance of a process against key metrics over time.

At the more sophisticated end, Six Sigma applies tools such as regression analysis and design of experiments in order to isolate the root causes of variation and test hypotheses.

DMAIC

A central element of Six Sigma is the DMAIC approach to solving problems. DMAIC stands for:

- Define – the problem

- Measure – the current state

- Analyze – the Current State to identify the sources of variation

- Implement – improvements to reduce the variation

- Control – put in place controls to ensure that the improved performance is sustained.

Pareto Chart

A bar chart or graph that displays different categories in descending order.

The bars can represent frequency or time/money.

5S

5S methodology is used to create a more organised workplace.

Each step is named as follows (Japanese):

- Seiri

- Seiton

- Seisou

- Seiketsu

- Shitsuke

Seven Wastes

Taiichi Ohno, often regarded as the architect of the Toyota Production System, delineated the 7 wastes, commonly referred to as Muda.

The 7 wastes are:

- Overproduction

- Waiting

- Transportation

- Overprocessing

- Inventory

- Motion

- Defects

Flow

Flow refers to the seamless progression of tasks within the value stream, allowing a product to move from design to launch, order to delivery, and from raw materials to a finished product in the customer’s possession without interruptions, waste, or reversals.

Value Stream Mapping

A value stream map is a unique kind of process map. It concurrently illustrates the flow of both product and information within a business process.

With this integrated view, businesses can not only detect points of waste but also quantify them and understand the specific informational pathways that lead to such inefficiencies.

HISTORY OF SIX SIGMA

There are a range of people and organisations who claim to have founded Six Sigma, however the roots go back to the Total Quality Management (TQM) movement in the 1980’s, lead by W. Edwards Deming.

Japanese

The Total Quality Management movement was the first western (and especially US) response to the success of Japanese manufacturers (especially of cars and consumer electronics) in Western markets.

Recognising that the success of Japanese products was not the result of low labour costs, Western businesses looked for other factors driving this success. The answer was ironically found in Japan’s enthusiastic adoption of US manufacturing knowhow introduced in the post war period.

This American science-based approach to manufacturing was famously enunciated by Frederick Taylor in his Scientific Management theories, put in to practice by Henry Ford, refined through the 1930’s and reached its zenith during the Second World War.

During the post war reconstruction period, the US sent manufacturing experts such as W. Edwards Deming and Joseph Duran to Japan to assist the manufacturing sector back on its feet.

The Japanese were able to successfully adopt and improve these methods, aided perhaps by the Japanese culture of rigour, perfectionism and self discipline.

Read more: Japanese Lean

U.S.

Unfortunately in the US, economic success bred complacency and many of the learnings of World War II production were lost. The consequences of this loss of focus were then felt in the 1970’s and 1980’s when Japanese car and electronics manufacturers started taking market share in the US with products which were not only cheap, but of exceptionally high quality.

At the core of the Japanese approach, Total Quality Management and Six Sigma is the idea that quality and cost is not a trade off. That is, by improving quality (and reducing variation) in every step of a process cost is also reduced.

WHAT DOES SIX SIGMA MEAN?

In a normal distribution almost all outcomes will fall within plus or minus six standard deviations (Six Sigma) either side of the mean.

It follows therefore that if a process can be controlled so that the range of plus or minus Six Sigma falls within the range of acceptable quality (the specification limits) then defects will almost never occur. In fact “Six Sigma Quality” is usually taken to represent fewer than 3.4 defects per million products.

This actually represents a range of plus or minus 4.5 Sigma from the mean. A process producing Six Sigma Quality is therefore considered to be “capable” of achieving the required quality every time.

Just that brief explanation will help you understand that an understanding of statistics is a basic prerequisite of understanding Six Sigma.

THE SIX SIGMA METHODOLOGY

First off, Does Six Sigma Work?

The answer is a qualified yes, because many of the originating companies claimed large benefits from its deployment. A better question is whether Six Sigma is the best way to improve your business.

There are two key problems with Six Sigma.

Waste

First, it focuses on variation as the source of waste in processes. Excessive variation is an important source of waste in processes, particularly defects, but it is not the only cause of waste.

Often the waste is inherent in the design of the process such as excessive motion, too many steps, excessive batch sizes or long waiting times between processes.

This problem of focusing only on variation as the source of waste is partly addressed by Lean Six Sigma, which aims to incorporate lean tools within a Six Sigma framework. This is not, however to dismiss many of the underlying problem-solving tools.

They are very good and we often deploy them as part of lean projects; however they are specialised tools and will not provide the full answer for businesses seeking substantial operational improvements.

Six Sigma Belts Certifications And Examples Of How They Are Used

The second problem with Six Sigma and Lean Six Sigma, however, is the larger one and that is the method of deployment. Six Sigma is deployed through a structure of specialist process improvers who are trained to different levels of skill in the improvement techniques.

We define the different level by using coloured belts, similar to martial arts. These are also know as Six Sigma certification

White Belt

- Introduction Level: White belts have a basic understanding of Six Sigma concepts.

- Awareness: They’re aware of the process management and improvement methodologies.

- Not Full-Time Team Members: Typically not part of the core Six Sigma project team but should understand the philosophy and how it can impact the organization.

- Support Role: They might assist in local problem-solving tasks and support the broader initiatives by their organization.

Yellow Belt

- Foundational Knowledge: They have a more detailed introduction to Six Sigma tools and methodologies.

- Part-time Participants: Often participate as project team members, playing a supportive role in larger projects led by Green or Black Belts.

- Project Tools: Introduced to basic process improvement tools like 5S, the Seven Wastes, and basic data collection.

- Small-Scale Improvements: May lead small-scale improvement projects within their respective work areas.

Green Belt

- Intermediate Level: They possess deeper knowledge and skills in Six Sigma methodologies.

- Project Leaders: Often lead projects, especially in areas or functions where they work.

- Data Analysis: Proficient in statistical analysis and able to utilize various Six Sigma tools for problem-solving.

- Collaboration: Collaborate with Black Belts and Yellow Belts to ensure project success.

Black Belt

- Expert Level: Deep expertise and understanding of Six Sigma principles, including supporting systems and tools.

- Full-time Commitment: Often work on Six Sigma projects as their primary role.

- Leadership: Guide and mentor Green and Yellow Belts and are responsible for driving strategic projects within the organization.

- Advanced Analysis: Proficient in complex statistical tools and often involved in process design or redesign.

Master Black Belt

- Elite Level: This is the highest level of expertise within the Six Sigma hierarchy.

- Training & Mentorship: Responsible for training and mentoring Black Belts and Green Belts.

- Strategic Implementation: They often help in the formulation and implementation of strategic goals.

- Advanced Problem Solving: Capable of solving the most complex organizational challenges.

- Organizational Leadership: Often play a role in driving the overall Six Sigma program and culture within an organization, influencing strategy and policy.

As previously mentioned, the levels of training correspond to martial arts belts.

Therefore a Green Belt can lead basic problem solving activities and simple projects, a Black Belt can train green and six sigma master black belts, lead more complex projects, and carry out more advanced analysis, and a Master Black Belt can train black belts and will generally run the whole Six Sigma program.

In my opinion, this is a resource hungry, bureaucratic big company approach.

It was designed by large bureaucratic companies (GE and Motorola for example), and I have only seen it work effectively in those companies, and even then, I am sceptical.

For most companies the time, training, and resources required to create a Six Sigma or Lean Six Sigma infrastructure of training and belted specialists are unsupportable.

The other big problem with the deployment approach is that it tends to make problem solving and improvement the job of the specialists, rather than every employee’s job. In particular Six Sigma activities often become divorced from key activities and strategic goals of the business and become a burden on bottom line and management rather than a support.

As one plant manager once told me: “I don’t think my budget can afford any more Six Sigma projects.”

When an improvement effort is seen as costing money rather than saving money, then its usefulness is very limited.

WHAT IS THE DIFFERENCE BETWEEN LEAN MANUFACTURING AND SIX SIGMA

While Six Sigma and Lean Six Sigma are both means to deploy improvement through a business, Lean is a complete management system (the Toyota Production System).

Six Sigma and Lean Six Sigma use a project management based deployment approach, where Black Belts and Green Belts are first trained in the improvement tools and then seek out projects to apply those tools on.

Lean Practitioners on the other hand look to change the whole organisation from the top down and the bottom up (usually simultaneously) in order to build a business that is inherently less wasteful, more responsive and Leaner.

A key element of Lean is the idea of Policy Deployment, where an active two way dialogue about strategy is maintained through every level of the organisation, ensuring that improvement effort is focused on the key strategic issues.

So what is the difference between Lean Manufacturing and Six Sigma (and Lean Six Sigma)? Firstly Lean and Six Sigma are both children of the same parent: the post war Japanese manufacturing boom. Both trace their roots back to Japan.

In the case of Six Sigma (and Total Quality Management) the link is to a wide range of Japanese companies through the work of US experts such as Deming and Duran, while with Lean the roots go back to one company, Toyota.

The term Lean was introduced by US and UK academics who had studied the global automotive industry and coined the term “Lean Manufacturing” to describe the unique approach to business adopted by Toyota that was the foundation of its staggering success. To learn more read our article “What is Lean Manufacturing”.

As mentioned in the previous sector, Six Sigma focuses on variation reduction, whereas Lean Manufacturing focuses on every resource and every activity in the business that does not add value to the customer, defines this as waste and seeks to minimise this waste.

Typically Lean Manufacturing describes eight types of waste. Variation is a source of some of this waste, but not the only source, the design of the process is often a much larger source of waste. Often focusing on variation alone will lead to optimisation of a broken process, Lean Manufacturing tool “Value Stream Mapping” enables businesses to identify how the process is broken and the best way to fix it and eliminate the waste.

This often leads to large step change improvements in overall business performance.

Read more in our Lean vs Six Sigma article

WHICH IS BETTER, LEAN MANUFACTURING OR SIX SIGMA?

In our experience and in the experience of the overwhelming majority of companies we work with, Lean Manufacturing is a far more effective approach to improving your business.

By aligning improvement to business strategy, and addressing the whole business, Lean Manufacturing is more likely lead to change in underlying culture and leadership practices that will sustain continuous improvement. Lean Manufacturing also makes improvement and solving problems everyone’s business, not just the job of elite problem solvers (Black Belts and Green Belts).

By looking beyond variation, Lean Manufacturing enables businesses to completely re-think the way things are done and make big step change improvements.

Lean Manufacturing’s focus on creating value for the customer also ensures that resources are focused on improvements that deliver the maximum benefit for the customer and for the business.

Six Sigma has some great tools though.

We often use “Six Sigma” problem solving and analysis tools such as SIPOC charts, Fishbone Diagrams and Design of Experiments when solving complex problems. However most problems are not complex to solve and that’s where the simple and effective Lean approach has the edge.

Read more: Cynefin Framework with 5 Domains explained

FREQUENTLY ASKED QUESTIONS ABOUT SIX SIGMA

Can Small Businesses Use Six Sigma?

While Six Sigma is known to be suitable for larger companies, it can be used for small businesses too, with some modifications to processes.

What Are The Benefits Of Six Sigma?

There are several benefits to implementing 6 Sigma, with the big ones being:

- Process Improvement

- Cost Reduction

- Improved Quality

- Customer Satisfaction

- Data-Driven Decision Making

- Competitive Advantage

Read more about Six Sigma vs Lean in our Blog

Learn More about Lean Manufacturing terminology in our Glossary.