Glossary of Lean Terms

There is a lot of lean jargon, terms, acronyms and “funny” words when you get started with your Lean journey. To help you cut through all the Lean Jargon, TXM Lean Consultants have put together the meanings of the core Lean terms and how they can used to improve your manufacturing processes.

Knowing the definitions of Lean terms is important to learning how to apply them when building a lean manufacturing system. These terms are not just to be talked about; they need experience from in implementing them. Indeed, lean principles are the foundation for a great production system and will always work best when combined with respect, humility, flow and fix. It is by no means an extensive lean glossary and will be added to on a regular basis.

| Term | What is it? | |

|---|---|---|

|

5S |

Workplace organisation tool that standardizes a work area by:

|

|

A3 Plan |

An A3 plan is simply a business plan or project plan expressed on a single A3 sheet of paper. A3 plans are used for summarising and explaining strategy (see also Hoshin Kanri), presenting projects and solving problems. By limiting the format to a single A3 sheet of paper and applying rules around layout A3 plans ensure that the essential information is communicated in a clear and concise fashion. |

|

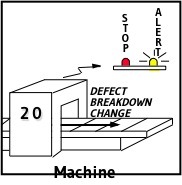

Andon |

A visual feedback process that indicates a person has a problem in production or in part supply and needs assistance to fix the problem. |

|

Chaku Chaku |

Meaning “load load,” Chaku Chaku is an efficient style of production in which all the machines needed to make a part are situated in the correct sequence very close together. The operator simply loads a part and moves on to the next operation. Each machine performs a different stage of production, such as turning, drilling, cleaning, testing or sandblasting. |

|

Continuous Flow |

One element of a Just In Time system is continuous flow, where the production Understanding Flow; how parts move along the processes, between each workstation and what this looks like across the minute, hours, shift, day, week and month. The future state value stream map has provided a vision for what the Production Continuous flow is also known as one piece flow |

|

First In, First Out (FIFO) |

Defined as a queue of materials in which the first item in the queue is handled first, the next one coming is handled second, and the last one to arrive in the queue is handled last. FIFO is a necessary condition for pull system implementation. The FIFO sequence is often maintained by a physical area that holds a certain amount of inventory. |

|

Gemba (Original Place) |

Usually taken to mean the place where value is actually created for the customer – the factory floor or workplace. To truly understand a situation one needs to go to “Gemba” or, the ‘real place’ ‘the place where the truth can be found’ – where work is done. Going to the “Gemba” is a key habit of Lean Leaders. |

|

Hansei (Self Reflection) |

To acknowledge your own mistake and to pledge improvement. Deep personal reflection. Using mistakes as a chance to learn rather than a chance to criticise is a key principle in lean thinking. Definition contributed by Tamera Lank at Tobul Accumulator |

|

Heijunka (Level Scheduling) |

Heijunka is a Lean method for reducing the unevenness in a production process The term Heijunka comes from Japanese and literally means levelling. It can help you react to demand changes and utilise your capacity in the best possible way. By implementing Heijunka, you can stop producing work in batches and start

|

|

Hoshin Kanri (Policy Deployment) |

Hoshin Kanri is the term used to describe the system used by Toyota to deploy its strategy through every level of its organisation and also receive upwards feedback on the strategy. Hoshin Kanri uses A3 Plans to communicate strategy at each level. |

|

Jidoka (Autonomation) |

Giving machines the ability to stop working when an abnormal situation is automatically detected, allowing operators to multitask. Read about Lean techniques to improve quality |

|

Just in Time |

All production parts, consumables and sub-assemblies are pulled into the production according to customer demand, as opposed to the traditional pushing production based on a central schedule or ERP / MRP system, regardless of current requirements or situation. |

|

Kaikaku (Radical Improvement) |

Japanese for meaning the “radical improvement of an activity” to eliminate non-value-adding waste. Usually implying “big step” changes rather than small step “kaizen” improvements. (definition provided by Richard Nichols at the Bradbury Group) |

|

Kaizen (Change for the Better) |

Applied to business organizations, it implies continuing improvement involving everyone. It usually refers to continuous small step improvement over a sustained period of time.Kaizen usually happens at the “Gemba” or workplace. Definition contributed by Tamera Lank at Tobul Accumulator |

|

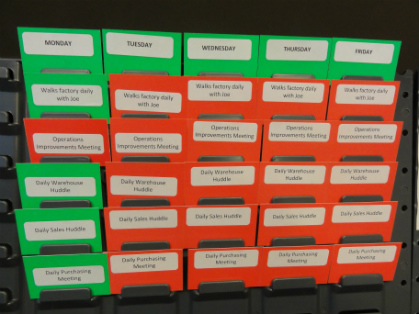

Kamishibai Board (Red-Green Task Board) |

A system whereby coloured “tee cards” are used to represent routine tasks in a workplace. In the typical application, the tags are printed red on one side and green on the other. They are then flipped from red to green as tasks are completed. Purchase Kamishibai boards and t-cards |

|

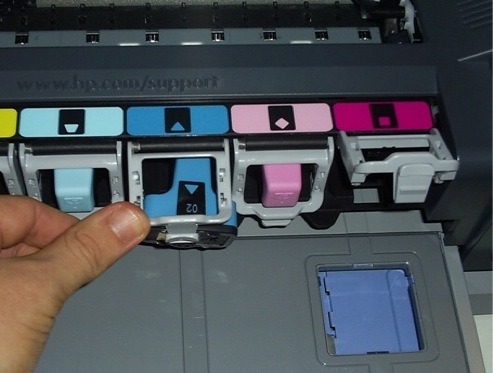

Kanban (Pull system) |

A process to signal the need for work, either for Production to make something or For Kanban the signal is a physical indicator – it may be a card, an empty box or a returned trolley. Implementing a Kanban system will highlight many problems in your production |

|

Lead Time |

A lead time is the latency between the initiation and completion of a process. Manufacturers review lead times across manufacturing, supply chain management and project management during pre-processing, processing, and By comparing results against established benchmarks, you can determine where inefficiencies exist. Reducing your lead time can make your operations more efficient and profitable. |

|

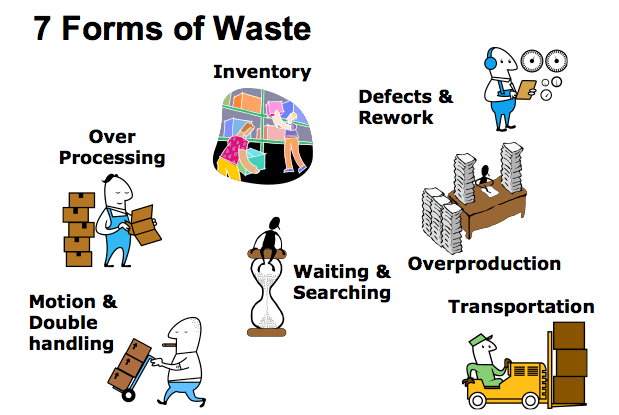

Muda (Waste) |

Anything in the process that does not add value from the customer’s perspective. Toyota realised that most of what happened in their factories did not add value to It classified this waste into seven categories. |

|

Mura (unevenness) |

A Japanese term meaning unevenness, irregularity, lack of balance. Mura is of the key causes of waste in processes – unevenness or imbalance. Use of Heijunka is aimed at eliminating Mura through leveling the rate of production. |

|

Muri (Overburden) |

Japanese term meaning overburden or overloading. Muri is another key source of waste. This means when processes or people are overloaded beyond their capacity. Muri can lead to problems with poor safety, poor quality and inconsistent output as excessive output can not be sustained leading to unevenness or Mura. |

|

Operational Excellence |

Operational Excellence is the execution of the business strategy more consistently Two companies with the same strategy, the Operationally Excellent company will |

|

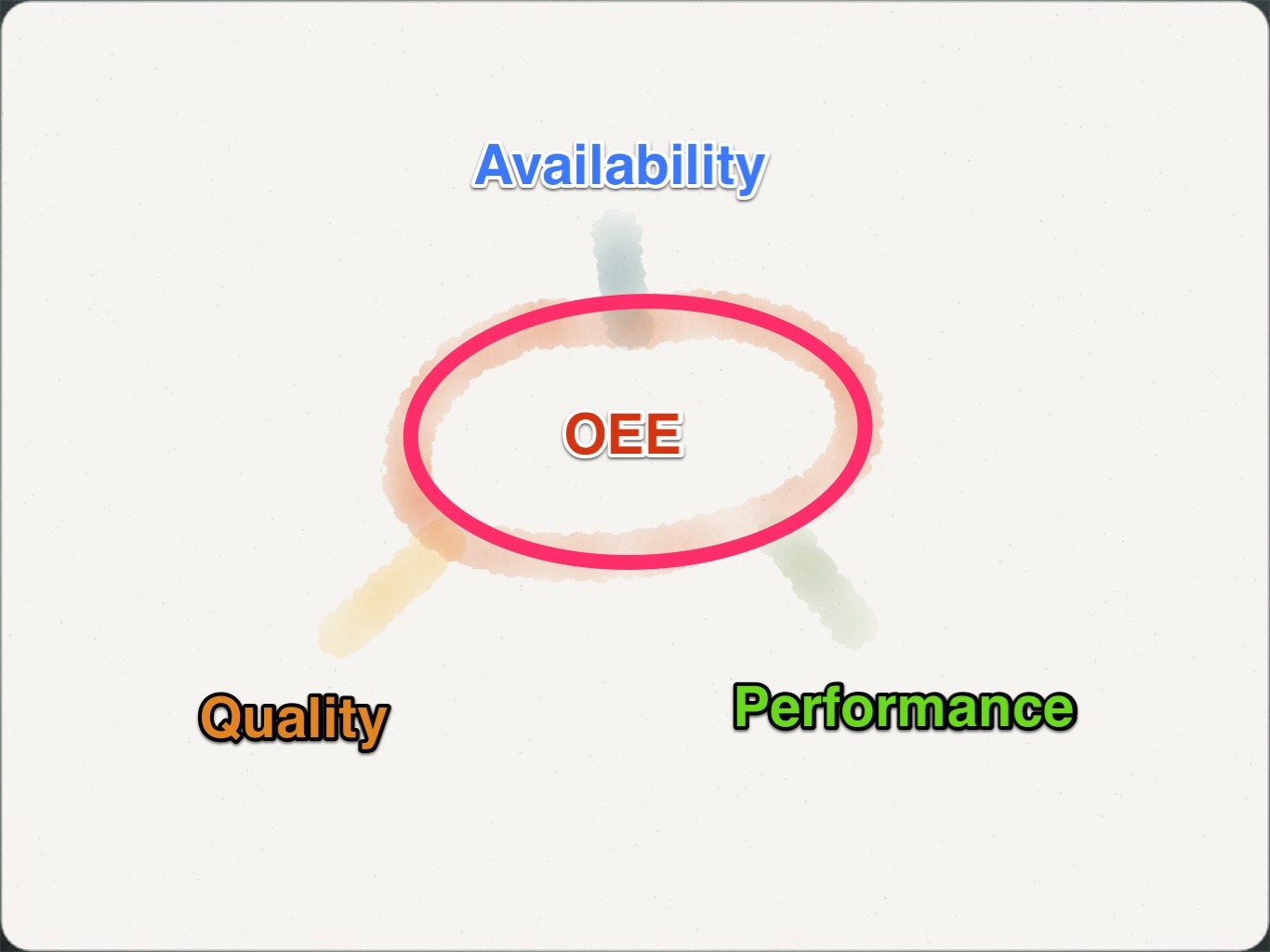

Overall Equipment Effectiveness (OEE) |

The origin of OEE is from the Japan Institute of Plant Maintenance and is a key OEE is a performance measure commonly used to monitor successful improvements to a process/area/machine. OEE is designed to indicate how effectively a manufacturing operation is utilised and is mostly applied to critical or constrained processes. OEE can at times be a complicated metric to understand as it is derived from three individual calculated components. The components of OEE are : Availability, • A = Represents the percentage of scheduled time that the operation is available to OEE= (AxPxQ) |

|

Plan Do Check Adjuct (PDCA) |

Plan, Do, Check, Act or Plan, Do, Check, Adjust is an iterative four-step management method used for the control and continuous improvement of processes and products. At it’s core it is a problem solving methodology. PLAN – This is where you take the overall situation and determine the steps DO – This is when a solution is devised and is implemented. There may be a mini CHECK – Just because you have put a new system into place doesn’t mean you ACT/ADJUST – Now we compare our checking outcomes against our plan. If we |

|

Poke Yoke (Error Proofing) |

Methods that prevent or detect defects in products. Error Proofing is the use of any automatic device or method that either makes it impossible for an error to occur or makes the error immediately obvious once it has occurred. It is a common process analysis tool. Our 12 tools for Lean Manufacturing article talks about Poke Yoke / Error Proofing in more detail |

|

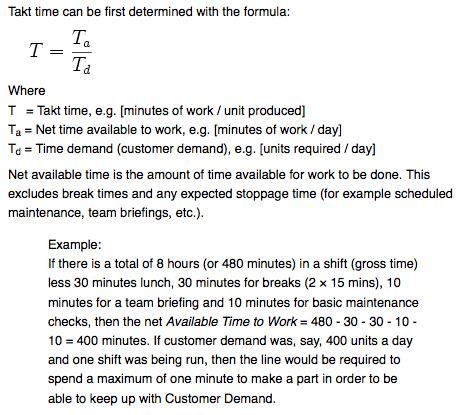

Takt Time |

Is the average time between the start of production of one unit and the start of TAKT Time can be used in a variety of manufacturing applications from production to control tasks like testing machinery or production quality. It can also be applied across administration tasks. It is most common in production lines with a product moving along a line of stations that each performs a set of predefined tasks. Automobile manufacturing is a classic example but doesn’t limit its use to just large businesses. SME’s can benefit from the introduction of TAKT Time just as much. |

|

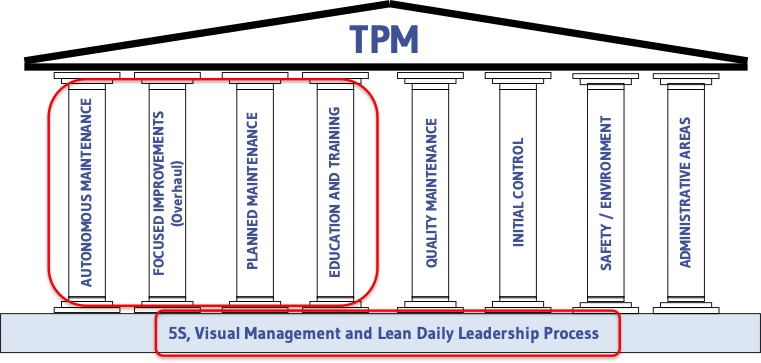

Total Productive Maintenance (TPM) |

Total Productive Maintenance is one of the more advanced Lean Enterprise tools and once Production flow, set up reduction and good housekeeping are in use, it becomes important to keep your machine uptime at it’s best. Running closely in parallel with 5S, TPM is the process where the operator becomes involved with the regular, daily maintenance of their machine. The targeted machine needs to be thoroughly cleaned and any maintenance issues fixed; the aim is to return the machine to a brand-new condition. |

|

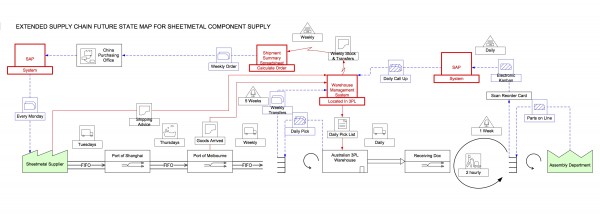

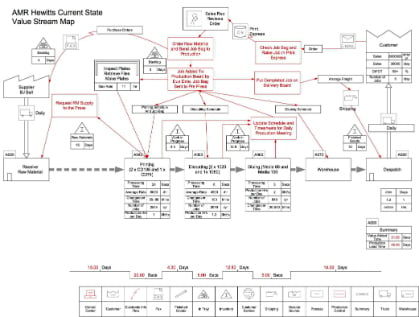

Value Stream Map |

Value stream mapping is a powerful lean manufacturing technique used to document, analyze and improve the flow of information or materials required to produce a product or service for a customer. Specifically, a “current state” value stream maps identify the value and waste in a process flow enabling the development of a “future state map” to eliminate that waste. Definition contributed by Tamera Lank at Tobul Accumulator |