Lean vs Six Sigma – Which Should You Choose?

The realm of business has its ripe points of contention, and the Lean vs Six Sigma debate holds a prime spot.

Experts often argue over the better blueprint for cost crunching and waste wiping. And for good reason!

After Lean, Six Sigma is probably the most popular process improvement methodology in the business world.

As a business starting out on the improvement journey, it can be hard to decide which approach to take.

Let’s take a look and determine if one is truly superior, or if perhaps they can join forces for an unbeatable alliance – Lean Six Sigma, anyone?

Six Sigma

As lean practitioners, we define waste as everything that happens in a process that does not add value to the customer.

Essentially if the customer does not pay for it, then we look to challenge it. Six Sigma places heavy emphasis on the reduction of variation as a source of eliminating waste.

Even the name, Six Sigma, is a reference to the range in a normal distribution in which 99.999% of outcomes are expected to fall (i.e.. the amount of variation in a process).

Variation is an important source of waste, and the Six Sigma methodology will help us reduce variation and eliminate waste in a process, but what if the process itself is waste?

What if it can be redesigned to radically reduce cost, lead-time or quality problems?

TXM Article: What is Six Sigma?

Lean

Lean methodology is an efficient system focused on creating value in production by reducing waste.

The essence of Lean is to ensure that every step in the production process directly contributes to the creation of a product or service that customers would willingly pay for. Anything outside of this value proposition is deemed wasteful and should be removed.

The roots of Lean can be traced back to manufacturing giants like Toyota and Ford.

While Lean manufacturing (a component of Lean) is renowned for its cost-cutting measures, its primary objective is the eradication of inefficiencies.

Seven Deadly Wastes

The Toyota Production System (TDS) encapsulated this philosophy by identifying the “seven deadly wastes,” though some argue there’s an eighth. These wastes include:

- Overproduction: Producing more than needed can lead to unsold products.

- Waiting: Delays between manufacturing steps or awaiting resources.

- Transporting: Unnecessary movement of goods risking damage or inefficiencies within the production cycle.

- Processing: Redundant steps in production that can be combined or eliminated.

- Inventory: Maintaining excessive stock, which can tie up resources and capital.

- Excess Motion: Superfluous movements like excessive walking or lifting that might be reorganized for efficiency.

- Defects: Product flaws that require reworking.

- People: Overlooking the potential of employees or underutilizing their skills.

By addressing these areas, businesses can refine their operations, resulting in streamlined business processes, that are not only more efficient but also more profitable.

In essence, Lean seeks to make operations of lean systems as efficient, effective, and agile as possible.

Lean Six Sigma

Lean Six Sigma draws a number of Lean tools such as value stream mapping in to the Six Sigma toolbox to provide the “Black Belt” with the necessary techniques to address waste more broadly.

On the other hand, Six Sigma offers some useful tools to the Lean practitioner.

While simple qualitative problem solving and root cause analysis is great and will address most problems, knowledge of the more advanced statistics based problem solving tools such as run charts, design of experiments and regression analysis can be invaluable in solving highly complex and intractable problems.

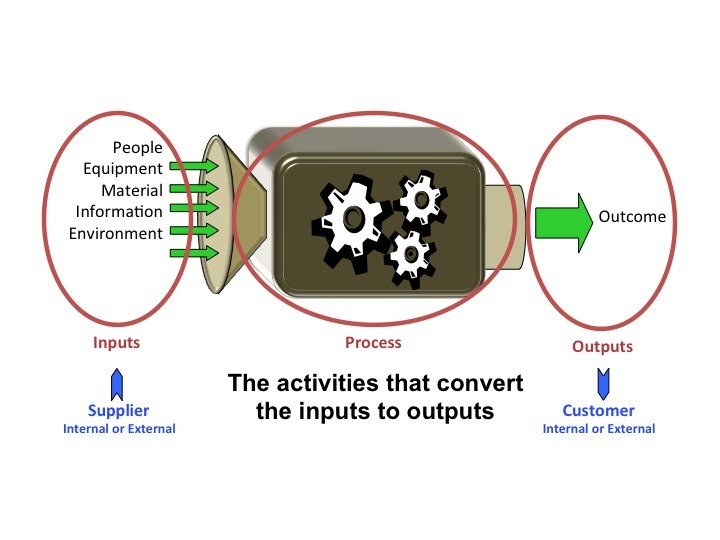

We also find some of the “Six Sigma” process analysis tools such as SIPOC useful, particularly for office-based processes.

Six Sigma vs Lean – What Are The Differences And Similarities?

At TXM we are committed to a Lean approach because we believe it is the most efficient system effective way to drive process improvement through an organisation.

However most of our team also have training in Six Sigma and we do assist some customers in deploying a Six Sigma or Lean Six Sigma approach. Both methodologies have similar origins, the post-war Japanese manufacturing miracle and western efforts to emulate it.

So what are the differences and relative merits of the two approaches?

Engaging Leadership

The biggest problem I see with Six Sigma programs is that they often fail to engage line leadership.

The Six Sigma ‘organisation” is usually set up as a ‘staff” function reporting in at senior level. Line managers are expected to deliver a level of improvement and are offered “Six Sigma Resources” to achieve these improvements.

However in my experience, the Six Sigma team are often frustrated because they cannot get line management interested in what they are doing and the projects on offer don’t always suit the “tools” they have. Line management are frustrated because they feel that the requirement to run Six Sigma projects is imposed on them and that the Black Belts are too choosy about what projects they want to focus on. As a result Six Sigma is seen as “another corporate initiative” and “extra work”.

The root cause of this disconnect between the Six Sigma Team and Middle Management goes to the “Lean Leadership” discussion that has been raging in Lean circles over the past five years.

Six Sigma often ends up being used as a means of delivering improvement tools rather than a driver of overall cultural change. It is essential that any improvement effort aligns directly with the business strategy and the daily process of creating value for customers.

Because Six Sigma connects to the organisation at the top and is trying to deliver change at the front line, there is often a disconnect and misalignment in the middle. Front line managers are primarily focused on leading their people to deliver value for customers every day. Improving this every day process is what will help them the most.

Lean Reducing Waste

A better approach, typical in “Lean” deployments, focuses on reducing waste in the main product value streams and building foundations of process stability. The Line Manager will “own” the value stream future state action plan and the project.

The selection of the future state value stream objectives (to reduce cost, reduce lead time, improve quality or all of the above) will usually be driven by the business strategy. As a result there is a direct connection between the Line Manager’s every day job, the things he is measured on and the improvement actions being taken.

The link between the strategy, the improvement initiatives and the manager is then his A3 Plan and the company’s policy deployment and process management.

Bulk Training Of Staff An Ineffective Use Of Resources

Most Six Sigma and Lean Six Sigma programs (and, unfortunately a lot of “Lean” programs) are introduced by a consultant running a series of training programs.

The consultant and the company (usually HR or Training) design the Six Sigma “structure” which determines how many black belts, green belts, yellow belts etc. are required.

The implementation plan then focuses on rolling out training to give individuals the knowledge of the tools that they need at their “belt” level. Projects then need to be found to apply these skills, reporting structures established to report on the projects and away the program goes.

This sounds great in theory, but is not the approach that has been proven to work in companies such as Toyota.

Teams And Leaders

In these organisations, coaching of teams and individuals over an extended period of time leads the best results (refer to Learning to Lead at Toyota, Stephen Spear, Harvard Business Review, May 2004).

Rather than teaching a whole range of tools through classroom training and simulations, tools are introduced as needed to solve specific issues in the workplace. Teams and leaders learn the tools by applying them and then the coach provides feedback on how they succeed at this.

Coaching tends to lead to longer term learning and is based on the teams demonstrating that they can apply the tools themselves rather than just completing a course and getting a certificate.

PDCA vs DMAIC

A key area of debate between Lean and Six Sigma practitioners are the relative merits of their problem solving “cycles”. In Lean we use a “Plan-Do-Check-Act” approach, while in Six Sigma the approach Is “Define-Measure-Analyse-Improve-Control”.

Really the two approaches have a lot in common. Their common parent is the use of scientific and lean methodologies to solve problems in business. PDCA is a simpler, more straightforward approach and we would see it as being used to solve the overwhelming majority of problems in a business.

PDCA problem solving can be driven down to every level of the organisation and be used to solve dozens of problems every day.

DMAIC is a much more detailed and rigorous approach. It is very effective for solving big complex problems.

Problem solving will generally need to be lead with someone with some technical skill. In Six Sigma terms, this person will at least be a “Green Belt”.

Summary Of The Differences Between Lean And Six Sigma Methodologies

Lean, Six Sigma and Lean Six Sigma have a lot to offer. The advanced statistical tools for analysing problems, and some of the process analysis tools are very effective and useful. The DMAIC problem solving cycle is also a very thorough and rigorous approach for solving big, complex problems.

For very large organisations (such as GE), where achieving overall cultural change is not a realistic objective, Six Sigma is an effective way to drive a level of process improvement through the streamlining business processes.

As I said at the start of this blog, at TXM we believe that a Lean approach is far more likely to lead to sustainable transformational change in your business. I usually summarise this by describing Six Sigma as a way to run a process improvement program, while Lean is a complete management system to run your business by.

There is some anecdotal evidence that adoption of Six Sigma and Lean Six Sigma are declining, including in some of the companies that developed it such as GE and Honeywell.

However it is built on some sound theory and practice and so, even if you adopt a Lean approach for your business transformation (as we recommend) an awareness of lean principles and knowledge of Six Sigma approaches will still be valuable to your business