As you and your company travel along the Lean journey, the ability for your team to identify and take part in solving their own problems becomes important. What often surprises us is that as we make progress, more problems seem to arise, not less as we often expect. It’s not that those problems weren’t there before, it was that they were hidden amongst the noise of the daily crisis and high levels of inventory and general day to day angst.

Having said that, not all problems are the same and therefore don’t need the same approach. With only a hammer, everything will look like a nail, so you need a range of tools in your problem solving tool kit. Our lean tools help to highlight these problems by making them obvious and increasing the need to fix them, rather than continue to work around them. Having a robust, multi level approach to problem solving help to make problem solving more achievable.

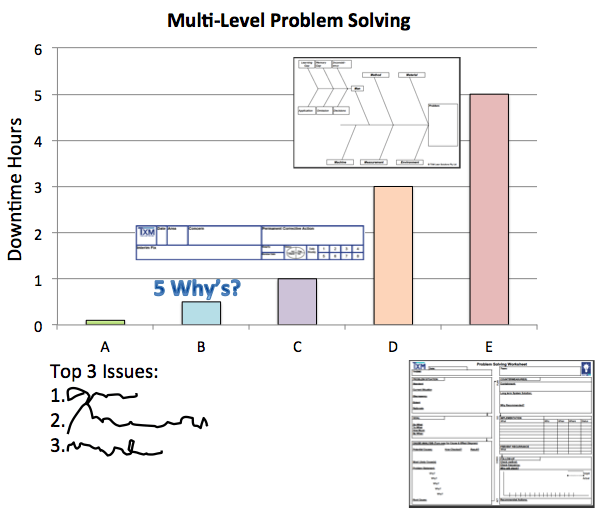

A Multi Level Approach to Problem Solving

Even the concept of multi level problems solving can be comforting; not only does it provide a scope to clearly define a range of practical approaches, it also makes it easier to train and engage your team, so they can solve problems that are relevant to them and at their level of concern.

A multi-level problem-solving steps approach may include, but is not limited to:

- discussing top 3 issues from a previous shift at SOS meeting

- small team 5 why’s to dig a little deeper into an issue

- concern strips to document a problem

- using a fishbone diagram to help focus your team’s brainstorming of possible causes

- A3 problem solving when a project approach is needed

Problem Solving Trigger Points

Trigger points are your company’s “rules” around when to jump into problem-solving mode, and at what level. For example, small line stoppages may not be enough to warrant a problem-solving activity, but if these small stops are happening with increasing frequency, then it may be time to put some attention towards it.

At the other end of the problem scale, major equipment failure may have occurred and you just need to get the lineup and running again; in this scenario, your team may need an A3 level investigation to identify the issues and investigate the most lies root cause. Having clear rules around when to jump into problem-solving mode and at what level will help your team be clear on what the company expectations are.

Each of the problem-solving levels your company uses needs to have a clear “Trigger” based on the functionality of your business and industry. You also need to consider who will be involved in problem-solving; when are the operators included? Or is it up to Engineering or Maintenance to determine what is going on?

How to Determine your Trigger Points

Trigger points to engage in multi-level problem-solving need to be developed with your product and support teams. What this looks like will be different for each company, depending on what industry you are in, how big your business is and how mature your team is with problem-solving.

At Toyota, an Andon light will be triggered when a problem can’t be solved within the defined time, often within a few minutes. For a continuous production line, a 30-minute downtime may trigger a 5 Why’s investigation. For industries with longer lead times, a 4-hour stoppage may highlight the need for further investigation.

Conclusion

To get started, determine a board guideline and then check to see how well your teams are going. The balance between making time to carry out a problem-solving activity and keeping production going will need to be discussed and negotiated. As your company matures through your Lean journey it will become clear that time spent solving problems with your team will provide a business return with reduced downtime and improve productivity.

Improving your ability to identify and solve problems efficiently becomes important as your Lean implementation progresses. Having a multi-level problem-solving approach, along with clear trigger points, can help your team understand when they need to jump into “Problem Solving” mode.