How often do you hear the term “PCDA” when it comes to discussing your company’s continuous improvement efforts? Seems like ALL the time, right? But what does it actually mean? Is it still relevant to our business in these global times?; it’s been around since the 80’s.

PDCA is still relevant and the core to our Lean Enterprise implementation.

Let’s revise the key features.

What Is PDCA? PLAN – DO – CHECK – ACT

Even before we jump onto the details, as with the cycle itself, we need to take a step back and look at where this fits into the whole implementation phase. We can use this approach for high level policy deployment, to address a quality issue or investigate a nagging problem.

PDCA stands for Plan – Do – Check – Act (or sometimes adjust) and is also called the Deming cycle as it was originally created by Deming as part of his Quality improvement process in the 1980’s. It includes a way of thinking to ensure the full cycle of continuous improvement is completed.

All too often, we come up with an idea to improve a process or system. Sometimes we get to the step of actually implementing it – which is great. But here the great power of the PDCA cycle is checking and acting on the results that come up for the Check step.

PDCA thinking can be used in many aspects of your business, from the highest level of company-wide continuous improvement, to person reflection on a daily basis. And it’s the reflecting, through the Check phase, and adjusting our behaviour or approach through the Act stage that will lead to the continuous improvement we seek.

Firstly we need to understand the context of our issue. Pascal Dennis refers to this in his book as “grasping the situation”; understanding what outcome we are trying to achieve, what is the current state of things and if there is a gap between the two. It is the gap between where we are and where we want to be that the PDCA cycle addresses.

Here are PDCA examples:

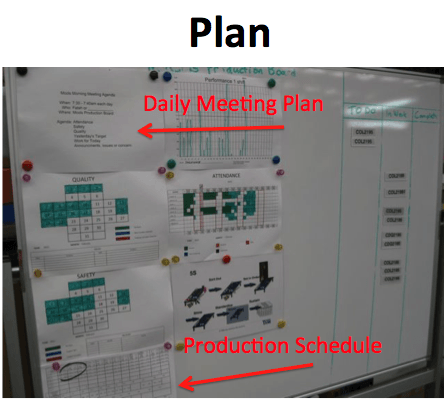

PLAN

This is where we take the overall situation and determine the steps that are needed to get to where we want to be.

Pascal Dennis also added that it is here that we must define our SMART metrics (simple, measurable, achievable, reasonable & trackable)

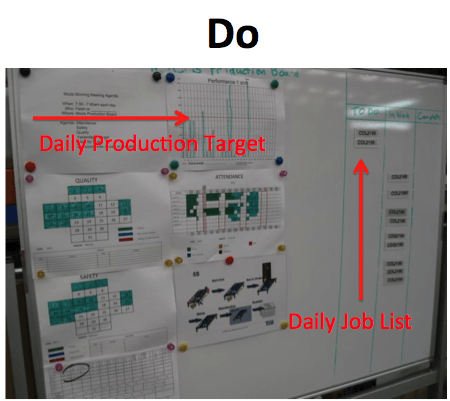

DO

Now we get started on our plan and put the steps into place.

There may be a mini PDCA cycle with each implementation step; planning what we are going to do, doing it, checking that section and adjusting, before moving onto the next big step. The challenge here is to check each smaller section but not get too caught up in the details when each small piece needs the other sections to be working to achieve our overall plan.

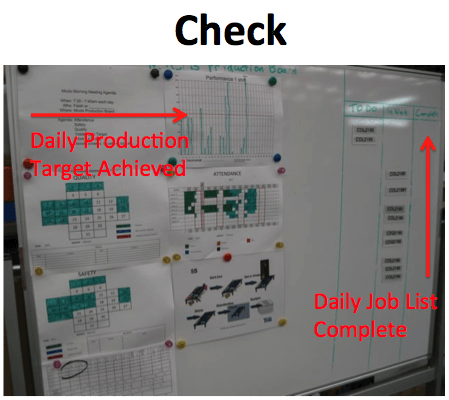

CHECK

Just because you have put a new system into place doesn’t mean you have finished.

We must check that our implementation is effective. This is where our SMART metrics help. Knowing how we will check that our actions have been effective and achieved the desired results is an important part of the process.

If we can’t measure the outcome, then how do we know we have done the right thing? Alternatively we may have solved one problem but not the one that needed solving.

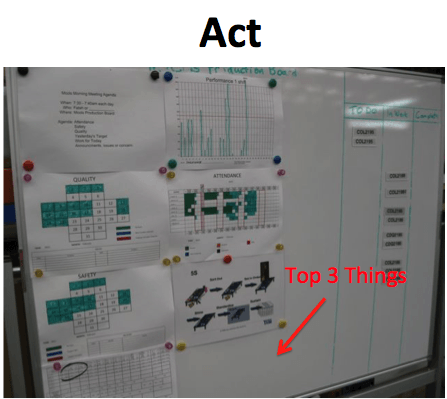

ACT

Now we compare our checking outcomes against our plan. If we have achieved the desired results, we document and standardise the process.

If our plan hasn’t been achieved, we repeat the process. Investigate what didn’t work, create a new plan, implement and check how it went this time.

- Using Fishbone Diagrams to Solve Problems

- Visual Management Boards 101

- Learn about the Cynefin Framework

In Conclusion: PDCA

Now take a few minutes to reflect on your current improvement activities; which phase is each project up to? Where does your process get stuck? Do you need to do more planning? Or is it the doing that gets your team caught up? How robust is your checking process? Is there anyone still there to review and adjust; or have they all moved on to other projects?

Improving your improvement processes will stand you and your company in good stead for the challenging times ahead!