What is Leader Standard Work (LSW)?

In Spear and Bowen’s seminal Harvard Business Review Article, Decoding the DNA of the Toyota Production System, the first “rule” of TPS was that “All work is standardised, to the extent possible, in terms of content, sequence, timing and outcome”.

This is an effective description of standard work, the way that that Toyota defines tasks for front line employees.

By defining the steps involved in a process, the sequence they need to run in , the time they should take and the outcome expected, standard work ensures the process delivers a consistent outcome and quality.

Lets Start with What Leader Standard Work is Not

If standard work is defining process tasks in terms of content, sequence, timing and outcome, it would seem logical that Leader Standard work would mean defining leadership tasks in terms of content, sequence, timing and outcome.

Quite a few Lean “experts” will tell you exactly that.

Templates

They will present you with templates where you can schedule your leadership day down to the last 10 minutes.

Many businesses try this and, in particular, attempt to inflict these rigid routines on their front-line leaders.

The result is frustration, missed schedules and a sense among leaders that they are “not doing it right”.

Why a Rigid Approach to Leader Standard Work Does Not Work

The reality, is that management research over several decades have shown that leadership practices cannot be rigidly scheduled. Leaders need to be flexible to respond to different needs and agile to adapt their response to different situations.

Simply adapting the process standard work approach to leader standard work does not allow the leader the ability to adapt to the unexpected customer need, the unhappy employee, the machine breakdown, the late delivery, the unexpected visitor or hundreds of other events that may occur during the day.

Of course, if leaders are totally reactive, simply reacting to what occurs during the day, then this is also ineffective.

Reactive Leadership Mindset

Reactive leaders simply spend their day putting out “spot fires” and never actually make improvement.

In fact, reactive leadership can actually make things worse as the reactive quick fixes for one problem create new problems in another area.

The result is continual chaos and a very stressful and unpleasant working environment for team members working with that leader.

The Need for the Right Level of Structured Activities

Routine And Structured Activities

So, leaders need a level of structure to enable them to focus on medium- and long-term challenges and on making improvements rather than just being consumed by the here and now.

This structure also ensures leaders find time each day to address all aspects of their role, rather than being consumed by a single crisis. Therefore, effective leadership is usually a mix of reactive and planned work.

For many leaders maintaining this mix of planned and reactive work does not come naturally. Some are hooked on the adrenaline rush of troubleshooting – reacting to today’s crisis and “saving the day”.

Introverted Leaders

Others may be introverts, more comfortable behind their desk completing administrative tasks or building ever more complex spreadsheets to analyse their process. Therefore leaders, particularly new leaders, need help to ensure that their day includes a mix of planned and structured activities, allows them to engage with all aspects of their role and allows time for them to react effectively to problems or unexpected events.

Leader standard work is an effective way to help leaders to get this mix of activities right and to get in to positive leadership habits.

Creating Leader Standardised Work Processes

To help leaders achieve this ideal mix, we use leader standard work. Leader standard work is a plan of regular daily, weekly and monthly tasks that each leader needs to complete. As with many of our standards, the aim we are looking for is a simple one page document that lists all the tasks and meetings that need to be done each day or during the week.

Creating standard work starts with the weekly structure of production cycles and meetings. Defined meeting times lay the foundation for the tasks a team leader needs to cover. Next are the list of tasks to be done each day and over the week. If there are preferred times to carry out these tasks, they can be written in.

If their completion is flexible in the day, these tasks can be defined as a list to check off as they are completed.

Daily Tasks – Routines

For a team leader, tasks may include a mix of things. technical tasks, such as routine checks on machines or random quality checks.

Team Leadership Tasks

Team leaders may need to check production schedules, tooling and material locations to make sure everything is ready for the next job.

The tasks may also involve leadership tasks such as making time to coach new skills to new employees, or simply walking the “gemba” to check in with team members through the day.

Middle Managers and Coaching

For more senior leaders or middle managers, there may be fewer technical tasks, but leader standard work may involve structured coaching other leaders or conducting regular “gemba walks” to stay in touch with what is happening where customer value is being created.

Weekly Tasks – Levelling the Workload

Weekly tasks need to be spread out over the week to level load.

The benefit of spreading these weekly tasks across the week is that increases the chances of completing them and making sure the important tasks get done, even when the urgent try to intrude.

Tasks like reviewing the auditing and checking on long term projects can also have a time slot.

Planning Monthly Tasks

Monthly routines, meetings and reviews can be tackled a few ways; for higher-level reviews, this may have a weekly time slot, but the meeting topic changes each week, for example:

- Week 1: Quality

- Week 2: Sales

- Week 3: Safety

- Week 4: Lean projects

This sets aside time for all people involved and creates the expectation of people begin in that forum at the set time.

Other monthly tasks may be defined as a list to check off as they are completed.

Reviewing these to make sure they are not all left to the end of the month becomes the challenge here.

Develop the Task Lists Collaboratively

We discussed earlier how the rigid “process standard work” to leader standard work can cause frustration and resentment among leaders. This can also occur with the more flexible approach that we recommend.

A top down approach to developing the routine tasks will often mean that team leaders get overloaded with tasks.

Frequently this is caused by “too many cooks” having input in to the routine tasks. Leaders end up overburdened with safety checks, quality checks, regulatory compliance checks, HR welfare checks, etc. etc.

Unable To Perform Problem Solving

This is absolutely not to say that safety, quality, HR and compliance are not important.

However as we know, inspection does not make quality and overloaded with checks, leaders will often, shortcut the checks, ignore the checks or, if they are overly conscientious or tending to introversion, spend all their time on these compliance checks and paperwork rather than on solving the real problems that impact safety, quality, compliance, employee engagement and operational performance in their area.

Coaching Leaders

Instead, we recommend a collaborative approach. Start with training the leaders in the principles of leader standard work and then ask them to develop their own plan and select their own tasks. Make it clear that this needs to cover all their responsibilities, including those for safety, the environment, compliance and employee welfare.

Help them review and refine their plan so that it covers their full range of responsibilities, but is also achievable every day.

Tracking Leader Standard Work With Standardised Work

Kamishibai Board

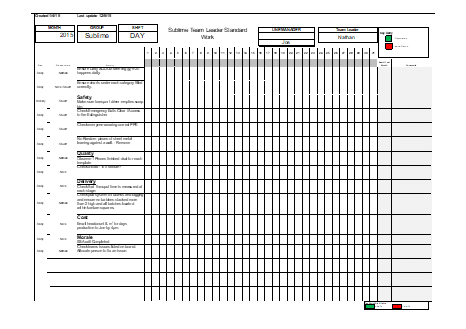

A simple way to keep on top of your regular tasks is to use a Kamishibai or tee-card board. As shown in Figure 2, T-shaped cards are arranged in columns according to days of the week.

The cards are labelled on both sides with the name of the tasks.

Cards start off with the red side of the card showing and then as tasks are completed during the week, they are flipped over to show green. This gives a highly visible indicator of progress in completing tasks during the week.

From the example in Figure 2 you can easily see that the photo was taken late on a Thursday, with only one task still to do that week and that a task was missed on Monday.

Visual Management Work Board

Kamishbai or tee-cards is just one way (albeit a simple and effective way) to track the completion of leader standard work.

Individual checklists or “working menus” are common. To keep things visual a central leader standard work board can be maintained for all leaders.

The main thing is that there needs to be accountability so that each leader knows that their compliance with their leader standard work routines will be checked and reviewed.

Getting Started

Once you have a draft of your standard work, commit to sticking to it for 4 weeks, noting what is working and what needs review.

Checking and reflecting on standard work and refining as needed will ensure your standards are robust and highlight where coaching is needed for the tasks that aren’t getting done – there is always an opportunity for problem-solving!

What’s in a Name, The Problem with “Leader Standard Work”

At TXM, we think the biggest problem with Leader Standard Work is the name, “Leader Standard Work”. This leads people to confuse it with process standard work and assume that the approach is the same.

Therefore, at TXM we tend to use the term “Daily Routine Leadership Tasks”.

We think this more accurately describes what is involved and avoids the confusion and unintended consequences, when people try to apply process standard work to leadership work.

Leader Standard Work is Easier than You Think

Leader Standard Work or Daily Routine Leadership Tasks sounds complex, but it is not. Just start by creating a list of the things you do and the things you need to do every day, week and month and go from there.

Don’t worry if it does not work first time. Inevitably you will assign yourself too many tasks in your first version and not manage to complete them. This is fine, by trying things out and adjusting them as you go, you will learn what you can realistically complete.

In the process, you will also learn where your time goes and this might unearth opportunities to solve problems, redesign or delegate tasks and create more time for the tasks that really matter.

The Benefits of Leader Standard Work

Over the years, we have seen leader standard work deliver major benefits. Most importantly, it drives behaviour change in leaders.

- By requiring them to perform planned tasks that encompass their whole role every day, we prevent them from being totally reactive.

- It can also show why leaders are so busy and help identify solutions to reduce this unproductive work.

- Getting desk bound leaders out of their offices and engaging with their people will lead to higher levels of employee engagement.

- Leaders performing routine “health checks” on the process such as making sure that everything is ready for the next shift or the next day can eliminate a lot of non-value-added time.

Leader standard work has sometimes got a bad name because of the rigid, top down and impractical way some people try to implement it. However implemented well, it is a powerful tool to maximise the effectiveness of leaders in your business, boosting continuous improvement and Standard Operating Procedures or (SOPs).