The Seven Habits of a Highly Effective Lean Leader

(Apologies to Steven R. Covey)

I am often bemused by the “Lean Leadership” discussion, as I think it self evident that strong consistent leadership is essential to the success of Lean just as it is to every major change or initiative that your business is going to attempt. In short, if the boss doesn’t support it, it is not going to happen.

So what is special about a Lean Leader and how do you become a Lean Leader? Firstly, you can’t change who you are as a person – your underlying values, your personality.

A lot of managers attempt this and end up simply coming across as unconvincing or worse, untrustworthy. So you can’t change who you are, but you can change what you do. That is, you can change your behaviours, which is where habits come in.

We all have habits – automatic behaviours that we demonstrate without thinking (meaning they are often driven by our subconscious rather than conscious thinking). We can change habits, but it takes discipline. The key to being a successful leader and particularly a Lean Leader is to demonstrate positive leadership habits

So what are the habits you need? So here they are – the “Seven Habits of a Highly Effective Lean Leader”.

1. Going to the Gemba

This is not just going for a walk and a chat once in a blue moon. Value is created on the factory floor and therefore manufacturing leaders (and leaders in any industry) need to spend time with their front line employees every day. This means taking time to observe the process, and provide constructive feedback on what you observe.

2. Notice Performance

The purpose of visual controls and visual management is to visualise the status of production and highlight abnormalities. However this is only effective if leaders notice these abnormalities. If you walk past and ignore, for example, an overflowing FIFO lane, equipment not in the correct location, a large stock of defective products or empty kanban locations you are sending a message to your people that these issues are not important. Your people will respond to what you see as important and therefore by ignoring things that are not right (we call it “passive acceptance”) you will fatally undermine your production system.

3. Ask Why Five Times

As leaders and managers we often see our role to direct and control. In the seminal HBR article, “Learning to Lead at Toyota”, Stephen Spear explains that at Toyota Leaders see their roles as coaches, teaching their teams to “observe and experiment to improve the process”. To do this means focusing on asking questions rather than giving orders. However when you ask “why”, be prepared to go beyond the superficial answer (“the operator made a mistake”) to get to the root cause. By doing this you learn the real opportunities in your business, but more importantly you teach your team member to go beyond the obvious and look for the root cause of problems.

4. Meet Every Day

In my experience as a manufacturing leader I found there was no substitute for regular structured communication with your team. We recommend that every leader meet with his or her team (direct reports) every day. This provides an opportunity to review performance, plan for the next day and solve problems. This meeting needs to be structured with an agenda, occur at the same time each day and take no longer than 10 minutes. We would usually suggest this meeting occurs standing up around the teams visual management board.

5. Demonstrate Standard Work

We don’t think that managers can break their day up in to blocks and structure their day in the way an operational task might be standardised. However for routine tasks, leaders need to demonstrate a standard process. This might be a standard way to run meetings, a standard approach to a Gemba walk, or use of 5S in your office. People follow the example of their leaders, so if you want your people to follow standardised process, then you need to do so yourself.

6. Think in Value Streams

A key plank of lean thinking is the idea of a value stream. This means seeing the organisation as the customer sees it, as a sequence of value adding processes delivering a product or service to the customer. If you want to really drive improvement through your value streams then you really need to make sure that your organisational structure, your business metrics and your personal focus is consistent with this.

Too often as managers we get focused on the need to “keep the big machine running”. Often this leads to overproduction. Instead we need to be focusing the team on meeting takt time and if the big machine has met takt time then it is better to stop it and redeploy the labour somewhere else.

7. Show me an A3 Plan

Expect that all major projects initiatives, updates are presented to you on a single piece of paper. This is a great tool to encourage your team to focus on what is important rather than presenting “death by powerpoint” or a 100 page report that no-one reads. However if you expect people to communicate to you in A3s, also be prepared to communicate your own projects and strategies in A3 format.

I am not suggesting that this is the definitive list, but if you establish each of these habits then you are going to give effective support the change going on in your business. The most important thing is to be consistent. One of W. Edwards Deming’s deadly diseases was a lack of consistency of purpose.

You need to therefore make sure that you are consistent over time in your messages and your approach. The key to forming and maintaining good leadership habits is repetition, so that they just become a natural way of doing things for you.

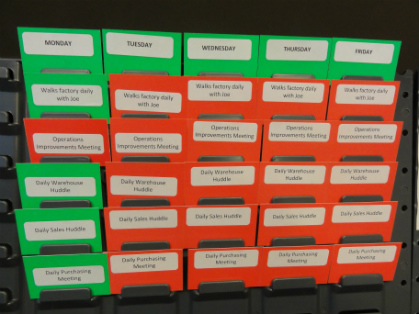

This repetition then creates trust with your team as they know how you are likely to behave and the things you are likely to do every day. Then the question becomes how to maintain habits. We recommend you consider setting up your own red-green task board (Kamishibai Rack) in a place where everyone can see it. That way you can apply a visual control to yourself to make sure that you keep to your new habits.

As I mentioned, there is a huge body of work on leadership. On Lean leadership some of my recommendations are

“Learning to Lead At Toyota”, Stephen J. Spear, Harvard Business Review, May 2004

“Getting the Right things Done”, Pascal Denis, Productivity Press, 2006

“Toyota Culture”, Jeffrey K. Liker and Michael Hoseus, McGraw Hill, 2008

And of course, how could I fail to mention:

“The Seven Habits of Highly Effective People” Steven R. Covey, Free Press, 1989

- Learn More About Using Red-Green Tee Cards (Kamisibai)

- Purchase Red Green Tee Cards and Racks on our E-store