What Are Metrics and How Do You Define Them?

Metrics are a key ingredient for improved communication in a visual Lean workplace and are essential for good Lean Daily Leadership (LDLP) Whether you are well established in using daily metrics, or just starting to set up your visual management board, it’s important to review your metrics to make sure they are still supporting your goals; remember, measuring data without action is waste! Here we will look into different types of metrics that may be suitable to support you, and discuss the importance of understanding which metrics are leading and which are lagging, and how to determine a balance between the two.

Important Metrics For Your Visual Management Board

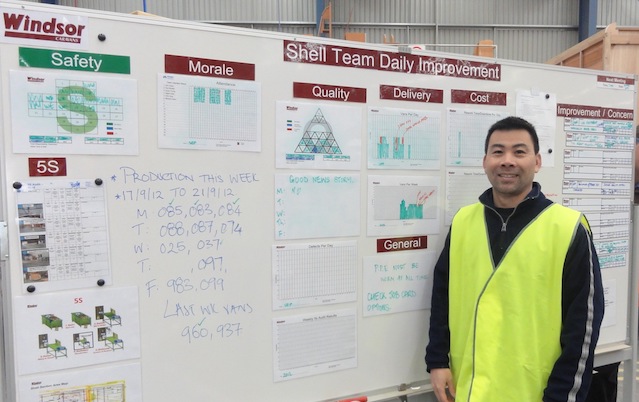

At TXM we insist you cover the basic metrics for your visual control board (also called a Production board) The metrics need to support the key factors that influence our business – Cost, Quality, Delivery, Safely and Morale. The order of these five parameters and the importance you place on them will depend on your industry, as well as your maturity along our Lean journey. In many workplaces, Quality and Safety will be considered the top priority to review each shift, with the other three following close behind. The order your company prefers is not as important as checking that all five are represented. The important issue is that each is given due consideration and included in the agenda for the daily review each shift.

When initially determining your team metrics, there isn’t a perfect formula to guarantee success. Choose simple metrics that are meaningful to your team. Aim for metrics that can be easily measured. We prefer items that can be counted, for example, the number of widgets completed this shift, over ratios or percentages. Also, we prefer to avoid metrics that require data to be delivered from other departments, managers or retrieved from a computer system. Ownership of the metrics will increase when your cell leader can get the needed information and then update the graph at a time that suits them.

Sometimes we are asked about using a computer screen to display visual controls. We prefer to keep it simple and in the control of the team by using paper graphs or graphs on a whiteboard. The act of gathering the data and filling in a graph gives the team control and ownership, and this makes the metrics meaningful to the team.

As your team continues to improve your metrics will need to be reviewed to determine if they are still meaningful and aligned with the goals of each area. If the current metrics still help the team meet it’s goals each shift, then they can stay. If the metrics are no longer helping the team, it is time to change them to a metric that is more meaningful.

What Is the Difference Between Lead and Lag Metrics?

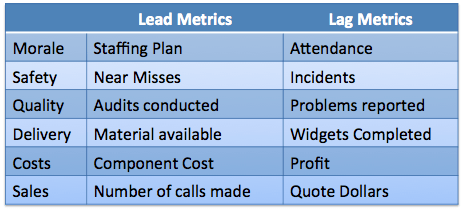

As we have discussed the overall importance of metrics, we can now focus on understanding whether our metrics are lead or lag metrics. A lag metrics is one that focusses on past performance, indicating where we have been or what has been completed over a period of time. Leading metrics are ones that show us the factors that can then influence our process and are based around input metrics.

Lag metrics are easy to measure, for example, how many widgets have we completed this shift? But lag metrics are hard to influence due to the complexity of our processes and the many inputs that are needed to complete our work. By contract, lead metrics are harder to measure but are easier to influence, and we can figure out the best ones to monitor to ensure out outcomes are on track.

Here are some examples of lead and lag metrics for the key factors of Cost, Quality, Delivery, Safely and Morale

Balancing Between Lead and Lag Metrics

When you review your daily metrics for each area, how do they look? Do you have an equal number of leading and lagging metrics? It is important to have a balance as the lagging metrics provide an overview of how the business is going, while the leading metrics give us an indication of how individual processes are performing. Understanding your processes and value streams will help you see where the leading metrics fit and how they can help to influence your lagging metrics.

Tips to Designing an Effective Visual Management Board

Conclusion

Getting the metrics right for your production control boards in an important part of implementing visual controls in a Lean workplace. Check you have a metric to cover the five key business factors of Cost, Quality, Delivery, Safely and Morale. Then review the metrics to make sure you have a balance of lead and lag metrics, and that the metrics support your team in achieving their goals each shift.