Sustaining Lean with Reliable Leadership Behaviours

Sustaining our Lean implementation is a challenge faced by every business, regardless of the industry you are in. As we progress on our Lean journey, it is easy to move onto the next theme. Having our efforts maintained and improved can only be achieved by monitoring the situation and adjusting as problems arise. The best way to make sure our systems are monitored is through the correct leadership behaviour. An audit is one way to define the required leadership behaviour.

Auditing in a Lean sense is not on the scale of a quality or tax audit. We have created our own rules and systems while implementing our Lean enterprise tools and our regular reviewing needs to be scaled to meet the system it is to check on.

Auditing Implementation

Every 2-6 months, it is wise to review your top-level A3 plan to check that your policy deployment is on track; with the business environment changing too quickly these days, we need to check that our underlying data used to set inventory levels and lead times are still current and relevant. Scheduling regular reviews of the top-level plan and data will ensure you are not caught by surprise when your systems begin to have trouble.

Auditing Production

Production is the lifeblood of all manufacturing companies and we need to check the health of our systems. Once we have checked our overarching plan and our underlying data, we need to regularly check we are meeting these requirements.

- Check to monitor the inventory levels and material flow throughout a production process on a daily basis. Spending a few minutes each day to walk the shop floor and note the inventory.

- Check standard work. Observe the work being done and look for waste. Use your peripheral vision to monitor multiple tasks and observe the workplace.

- Check problems are being solved – read the daily visual management boards and ensure the problems you are aware of are documented and that there are many other smaller problems being resolved.

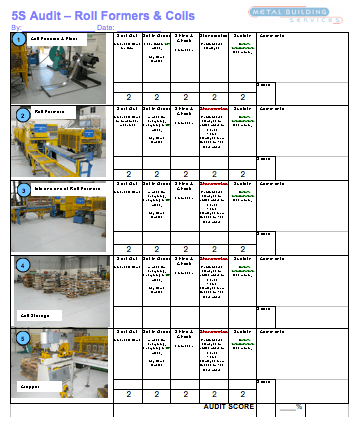

Auditing Housekeeping

Once you have your housekeeping and 5S standards in place, the expectation of a tidy workplace is set. Now we can monitor our team’s understanding of these expectations by weekly audits, based on the 5S standards already in place. Summarising these into a single audit sheet makes the audit simple. Our aim here is to identify areas that are not being maintained and looking for opportunity.

Conclusion

The key to sustaining Lean improvements is by routine Leadership behaviour. Auditing the systems and processes previously is a structured way of ensuring leadership behaviour. Having simple, visual aids makes them easy to complete so you can focus your attention on correcting the areas that are not begin maintained and finding further areas to improve.