What is Overall Equipment Effectiveness?

Overall Equipment Effectiveness (OEE) is a performance measure commonly used to monitor successful improvements to a process/area/machine. OEE is designed to indicate how effectively a manufacturing operation is utilised. OEE can at times be a complicated metric to understand as it is derived from three individual calculated components. The components of OEE are : Availability, Performance, and Quality.

To calculate an OEE for a single machine first you need to know your Availability, Performance and Quality.

OEE= (AxPxQ)

• A = Represents the percentage of scheduled time that the operation is available to operate. Often referred to as Uptime.

• P= The speed at which the machine runs as a percentage of its designed speed.

• Q= : The Good Units produced as a percentage of the Total Units Started.

How to calculated the components Availability, Performance, and Quality.

Availability is a measurement of Uptime.

Calculation: A = Available Time / Scheduled Time

Performance – is a measurement of speed

Calculation: P= (Parts Produced * Ideal Cycle Time) / Available Time

Quality – measures the Good Units produced as a percentage of the Total Units Started.

Calculation: Q = Good Units / Units Started

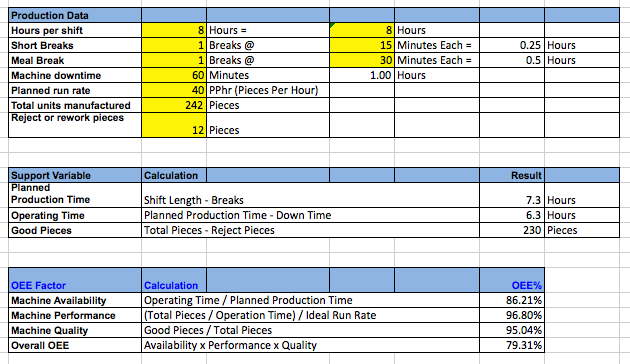

Here is a working example on how to calculate Overall Equipment Effectiveness (OEE) for a single machine example. First you need to know your production data in order to calculate the inputs for 1) Availability, 2) Performance and 3) Quality elements. These include:

- Hours per shift

- Total break

- Machine downtime

- Planned run rate

- Total units manufactured

- Reject or rework pieces

1) Machine Availability

The Availability is the measurement of the time the machine was able to performance its function.

Calculation: Availability = Available Time / Scheduled Time

Example:

The CNC Lathe is scheduled to run for an 8 hour shift.

The normal shift includes total of 45 minute meal breaks.

During the shift the Machine experiences 60 minutes of unscheduled downtime.

Scheduled Time = 8hrs – 0.75hrs break = 7.25hrs

Available Time = 7.25hrs Scheduled – 1 hours Unscheduled Downtime = 6.25 hrs

Machine Availability = 6.25hrs/ 7.25 Scheduled = 86%

2) Performance

The Performance Metric is a measurement of speed that machine needs to run in order to performance its function.

Calculation: Performance = (Total units Manufactured * PLanned Run Rate) / Available Time

Example:

Available Time = 6.25 hrs

The Planned Rate for the part being produced is 40 Units/Hour or 250 part per shift

The Machine produced 242 Total Units during the shift.

Time to Produce Parts = 242 Units for the shift

Performance = 242 / 250 parts = 97%

3) Quality

The Quality metric measures the Good Units produced as a percentage of the Total Units produced.

Calculation: Quality = Good Units / Total Units produced

Example:

242 Units were manufactured in order to produce the 230 Good Units.

Quality = 230 Good Units / 242 total units manufactured = 95.0%

These percentages can now be entered into the standard formula for OEE.

OEE= (AxPxQ)

OEE= (86% x 97% x 95%)

OEE= 79%

This calculation can be performed easily with spreadsheet template for daily measure to be added to a team’s production board.