Client PTE Hydraulics

Location Brisbane, Australia

Background

PTE Hydraulics is a Queensland based company specialising in the design and manufacture of hydraulic cylinders and rotary actuators for various industries, including agricultural, mining, transport, earthmoving, waste management, and manufacturing. PTE Hydraulics have been working with TXM since early 2022 when we helped them reconfigure their factory space after a feasibility study found they could invest in new machinery and rework their old facility, saving thousands of dollars in the process. The first project not only redesigned their facility but also organised their warehouse, separated their product lines, reduced WIP and improved lead times.

The Challenge

Since their first project PTE Hydraulics faced major challenges in their transition to a lean manufacturing. Their complex production schedule led to inefficiencies, with large batch runs and long lead times slowing responsiveness. Production was highly reactive, as supervisors set priorities daily based on immediate demands rather than a structured plan.

A lack of KPI monitoring made it difficult to track performance and drive improvements. Poor communication between departments further disrupted workflow, causing confusion in production. Operators often had to ask supervisors which job was next, leading to delays and inefficiencies. These issues created an unstructured production environment, making it clear that a lean approach was necessary to improve workflow, reduce waste, and enhance overall efficiency.

The Solution

With the guidance of Senior Lean Consultant Thomas Gieloff, PTE Hydraulics successfully overhauled its complex actuator production scheduling by introducing a simple and effective pull-based Kanban system. This shift allowed the team to improve flow, reduce planning complexity, and respond more flexibly to customer demand.

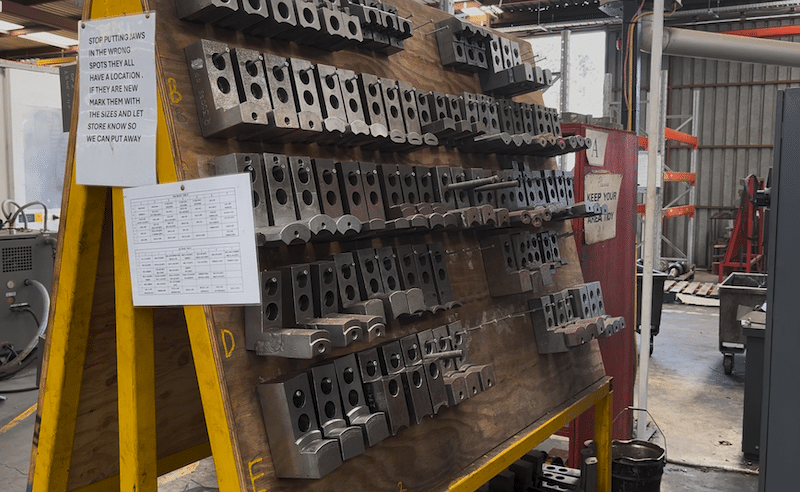

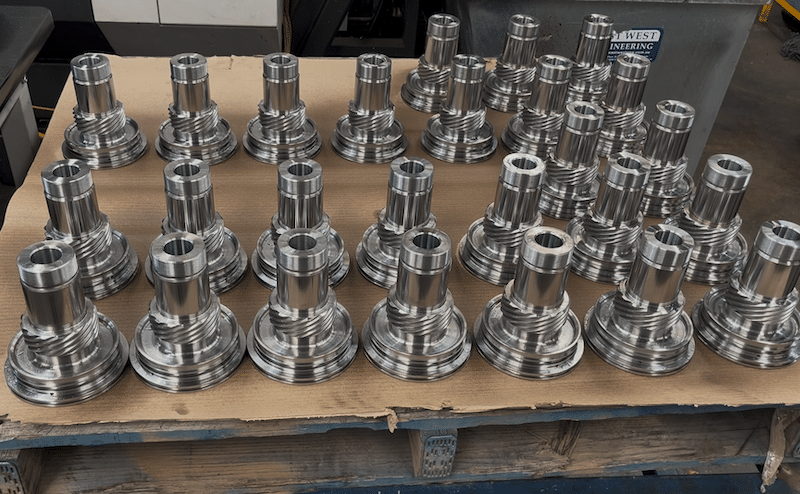

To further enhance efficiency, batch sizes were significantly reduced, lowering work-in-progress levels and freeing up valuable floor space previously occupied by excess inventory. A full site 5S implementation followed, bringing structured workplace organisation to every department and supporting a culture of cleanliness, order, and visual control.

A second major initiative was the introduction of Leader Standard Work and daily shop-floor meetings, also led by Thomas Gieloff. These practices created a clear, repeatable framework for frontline leadership and enhanced communication across teams. Operators now have daily visibility into what’s in production and where it is in the process, improving coordination and accountability across shifts.

The Results

These improvements have enabled PTE Hydraulics to simplify operations, reduce waste, and build a more engaged and responsive production environment. Some of the more notable results include:

- Over 30% reduction in Work in progress

- Lead times reduced from 50 – 60 days to 7 – 14 days

- Lead time of specific actuator part reduced from 30 – 40 days to 7 – 14 days