There is a lot of literature on implementing Lean in office and administrative functions and the concept is not new. However, I still see relatively few companies that have driven real sustainable change in their office processes through Lean. In our experience there are some key factors to ensure that your Lean Office efforts lead to sustainable results:

1. Start By Listening and Making it Relevant

Most Lean experts come from an operational (especially manufacturing) background and many are trained in engineering or another technical discipline. In the office, there are usually very few engineers and technical people. Start talking to a bunch of accountants or internal sales staff about “production”, “output”, “operators” and other “factory” terms you could find that your Lean Office initiative is very short-lived. Even if you do get some acceptance, you may not get the real level of understanding needed for the changes to stick.

People might make the changes initially, but if they don’t understand why they are doing them and how they are relevant to their work in the office, the changes won’t stick. This especially applies to the Lean Office “foundation” tools such as 5S, Visual Management, Daily Meetings, and Problem Solving. You need to learn the language of the Lean office and adapt your presentation to use this language. Avoid using factory examples (if you are starting out in the office and don’t have any Lean office case studies to share it may be better not to use examples at all!).

For this reason, it is important to spend some time at the start of the project just learning about the office environment, understanding the process and listening to the kind of problems that are experienced. And finally – forget all the Japanese jargon (unless you are in Japan). It is a huge turn off everywhere, especially in the office.

2. Understand the Key Office Value Streams

Our approach to deploying Lean is usually to start by value stream mapping the key business processes and developing a future state and action plan to improve performance. The same approach works in the office. To sustain Lean it has to be seen to deliver results. The most significant improvements are going to occur when you improve the main processes occurring in the office and the way to do this is to identify these value streams and focus first on improving them. You will need to build the foundation tools like 5S, visual management, leader standard work and problem-solving will be needed, but if you focus on these first you might find that the gains are small and gradual and hard to sustain. I like to say that Lean is sustainable when it ceases to be an “improvement initiative” and just becomes “the things we need to do to get the results we have to get”. This means making improvements to the way everyday tasks are done, which means improving the key value streams in the office.

3. Don’t Oversimplify

It is easy to get bogged down in complexity in an office environment, but it is also important not to over-simplify things. For example in a recent project in a sales organization, we looked at the process of generating a sales quotation. The temptation would be to view this process as one value stream. In fact, we decided that there were four value streams for generating a quotation, depending on the type of customer that required the quote. The processes in the four value streams were completely different. If we had attempted to develop a single “standard” quotation process it might have been used for a while, but very quickly exceptions and work abounds would have been developed, for example, to expedite “simple quotes” and to provide more detail for “major tenders”. By taking the time to develop four future state maps (there was some overlap, but they were distinctly different) our client then had the right tools for the full range of business quoted and the improvements have been sustained.

4. Respect Organizational Complexity

Organizational silos exist in manufacturing, but they are usually physically visible. The production flow across the silos is also clear and the logic of streamlining this flow is easy to explain. The manufacturing functions also all tend to report into the Manufacturing Manager, giving him or her control to change the plant structure to suit the value stream.

In the office, there tend to be even more functional silos and the flow of processes across these organizational boundaries tends to be less clear. Departments or Silos tend to have greater separation and usually report at the CEO level. For example in the sales process example I mention, quotations often involved four functional departments:

- Sales, who met the customer,

- Customer Service (who were part of the Supply Chain team), who took the order and planned the demand,

- Engineering who completed any application engineering and developed the bill of materials and routing and

- Finance who costed the job.

In the matrix organization, each of these functions separately reported into the CEO and separately reported to functional leaders in Head Office in France. Everyone would agree it would be better in theory if quotes were handled by one functional department (logically sales), but in practice, the Engineering Manager may be reluctant to allow an engineering design function to move out of his or her control, the Finance Manager may be worried that Sales will not maintain profit margins and the Supply Chain team may worry that sales will make promises that they can not keep. In the end, we got agreement to consolidate all the functions into a single “Sales Back Office” reporting to the Sales Manager, but this took a lot of detailed planning and careful design of processes, business rules, and job roles.

More often you will not be able to shift people between functional departments and will have to work with the organizational structure you have. Therefore, you will need to do a lot of work to ensure each function involved supports and is fully committed to change. It only takes one recalcitrant Functional Manager to fail to support the new Lean office process for the new process to fail. Initially, it can be good to just focus on one functional department, but given the way in which office functions work in close proximity to each other, it will be necessary to address value streams that cross organizational boundaries. When this happens, be prepared to put the time in to get the full commitment and support for the new processes across everyone involved.

5. Standardize the Work

In many offices, day to day business processes are not formally documented. Often Lean office improvements are implemented, but the detailed work instructions developed with these processes are never fully documented in the form of standard work. As a result, when people change and managers change the processes fall apart. It is therefore essential that when you develop your future state that you also develop standardized work instructions to lock-in that improvement. This does not need to be onerous, but it is an investment in time that will ensure that your improvement is sustained. It also provides a basis for further improvement.

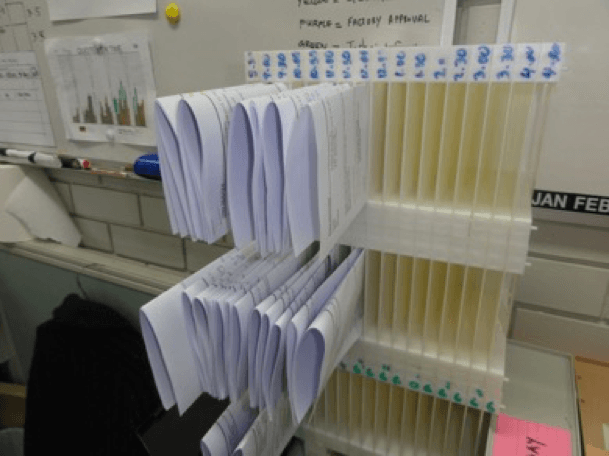

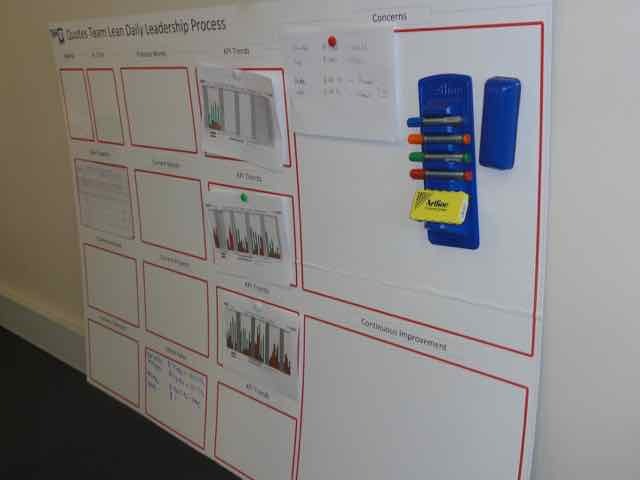

6. Keep It Visual

Office staff will often automatically look for an IT solution to solve process problems. While IT may be part of the solution, changes usually come at a high cost and long lead time. As well the impact of lean is often not visual so the status of work in the office can not be seen without running a report – if you get around to it. Simple visual controls such as load levelling boards, planning boards, pull systems and FIFO lanes work well in the office and make the work status visual so that everyone can see progress at a glance in real-time. Visual management using handwritten graphs and problem-solving concern strips ensure that teams really get to grips with their office key performance indicators rather than simply printing and posted computer-generated graphs. Visual management and visual controls might seem “low tech”, but the success of its office depends on the engagement of its people no matter how good the technology. “Hands-on” visual controls and visual management bring the team together to drive better office performance.

7. Align with Strategy

The problem I see with a lot of Lean initiatives is that they are done without a specific objective in mind. Lean is not a strategy, it is a tool to achieve strategic goals. Therefore your Lean initiative needs to be driven by a clear strategic objective. This ensures that everyone in the office knows WHY they are implementing Lean. It is not enough to say that “we need to improve” and lean is a good way to implement improvement. WHY do you need to improve? What are the specific outcomes you need to achieve? Why do these outcomes matter and why is Lean the best way to achieve those outcomes? When these things are clear, then it is much easier to get acceptance of the need to change.

In the sales back office project, I refer to the above, the term “Lean” was hardly mentioned. The project was about redesigning the sales back office process in order to deliver a better service to customers at a lower overall cost. This was driven by the need to respond to changes in the customer base and increased competition from imported products. Everyone understood the need for change and Lean was just seen as a means to achieve this necessary change, rather than an end in itself.

8. Don’t Be Too Much of A Purist

The office is not a factory and it is certainly not a Toyota automotive assembly line. Trying to drive rigid compliance to lean theory is not going to work in the office. Focus on retaining the core principles of Lean, but be prepared to innovate and develop practical solutions that suit the environment you are working in. 5S can be a particular problem. I hear horror stories of 5S “fanatics” insisting that anything “non-essential” be removed from desks including family photos other personal mementos and that locations must be specified for every item including coffee cups and computers.

This just alienates people and makes the workplace very stale and unpleasant. It also starts to look pretty silly. The aim of 5S is to standardize the work area in order to improve productivity. Focus on controlling and making visual the things that actually matter – the actual work. Remove unnecessary clutter (old files, junk, unused equipment, but remember the goal is productivity, not aesthetics.

9. Lead from the Front

You may wonder why this is not the first point on my list. However, I think it should almost go without saying. If the leaders are not committed and do not demonstrate that commitment, then no initiative in your business (Lean or otherwise) will be sustained. What this means is sending a consistent message through your communications, your actions, and your priorities. Practically if you are a business leader you need to talk about the lean projects, keep up to date with the progress, be visible, and give feedback on progress. Notice improvements, but also notice when things are not as they should be and ask why. The visual tools such as 5s controls and visual management boards that Lean provides are excellent for this as they provide an easy way for leaders to see when things are going well or when things are off track and to give feedback.

TXM Article: Learn the Top Six Opportunities to Implement Lean in the Office