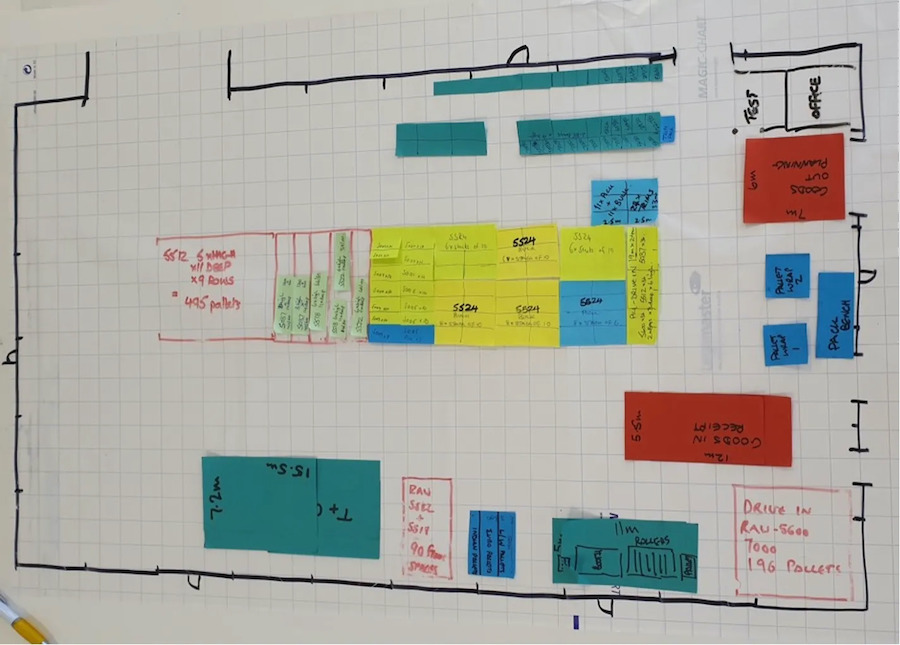

It’s much easier to determine the best alternative layout when each work centre is a different colour. For example, if you’ve got five different machines then make them five different colours. Keep the machines the same colour when comparing different layout alternatives.

Visual Workshop Process – Colour the Work Centres When Selecting the Best Layout

The different colours allow many people to become far more familiar with the layout in a shorter period. This allows far greater engagement from many people to quickly interpret the layout and find tune the detail. Many people from different areas can quickly understand the layout and give a meaningful contribution in a short time. The time it takes to fine-tune the layout is significantly reduced.

As alternative layouts are developed from creative concept to practical application, people that create the alternative are very proud of their creation. This pride is often because they thought of the idea and often personally brand the idea with a nickname, aligning their reputation to the success of the alternative. The use of different colours can really highlight the changes and help them stand out. Differences between alternative options are clearly visible.

The challenge is to capture as many innovations as possible. When reviewing the layouts, we synthesise the distinct advantages of each layout and incorporate that into new alternative layouts. The alternative historic way was to go straight to judgement. However, it is far better to identify the key benefits of each layout and encourage groups to create new and better layout alternatives that will be highly visual with the colour coding system.

This way of using coloured scale cut outs can be used in many different industries. Anywhere where a new workspace needs to be layout out. At TXM we have applied this thinking in factories, warehouses, offices, maintenance workshops, farms, produce sheds and container yards.