Creating a Lean Factory Layout

Often the TXM team are called in to help relocate factories or rearrange within the current walls to improve production efficiency. It can seem like an overwhelming task for many and by breaking it down into manageable steps it can be accomplished like any other project.

Plan

Before you start creating a scaled model or hiring a new CAD person to draw up your layout, you need to take a step back and evaluate your production requirements. By travelog along the Lean journey, you will already have created a few value stream maps. It is time to get these out and review them. These show you your production processes as well as how you join the parts together, indicating areas needed for supermarkets, FIFO lanes or Kanban squares.

Along with your VSM, you need to consider the flow of people, parts and information through the factory. By taking a few minutes to consider the needs of each for these elements, it is much easier to build them into your layout, rather than trying to fit them in after machinery has been moved.

Scaled Model

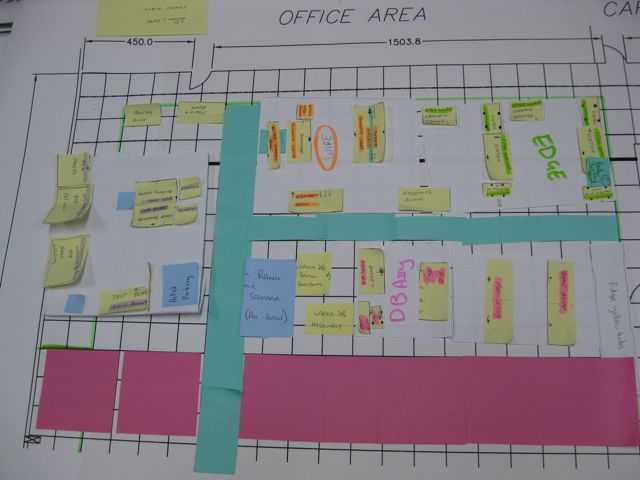

Once we have considered production flows and needs it’s time to get out the tape measure and create paper cutouts for each machine, workstation, trolley and anything else that is needed. Starting with a blank sheet, follow along your VSM and put the key equipment into place, constantly tailing with your team about the details of your production process; which side of the machine needs forklift access? What happens when that really long part gets made? Made adjustments as you go.

Repeat for Each Value Stream

Then fit your smaller cells onto your factory layout, making adjustments for shared equipment, building features and safety items.

When you have your first draft, take a photo or photocopy, then pull off the cells and create another layout. Then repeat this for a third time. Each iteration will increase your knowledge of what works and where the opportunities lie. Each iteration allows others ton to contribute.

Project Plan

Once your layout has been reviewed by all stakeholders, you are ready to draft up an implementation plan. When adding timing to your project plan, allow for contingencies, remembering that it is a rear occasion that all will go to plan. You must include a cross-functional team during the planning phase; schedules will need to be adjusted to provide a production window to move machinery, allowing time to reconnect and re-qualify, if needed. The Quality team will be able to outline the re-qualify or remastering procedures and provide time estimates for these activities. Good luck with creating a new Lean Plant Layout.