Client A Global Leading Abrasives Manufacturer

Location Shanghai, China

TXM Lean Case Study – Lean Transformation for Abrasives Manufacturer

The Challenge

Our client’s Shanghai plant has operated for more than 20 years with an enormous range of products using complex processes. With a new senior management team, their objective was to be number one in the Asia market within 3 years. However, to achieve this objective there were some obstacles that needed to be addressed.

This included: long lead time lead to late deliveries (On time delivery was less than 80%); more than 100 tons WIP in finishing areas; lack of standardisation; poor equipment maintenance; lack of people engagement and strong resistance to improvement and change.

The TXM Solutions

In order to reduce the resistance to change, especially from operators, TXM helped our client to select 2 pilot projects to do before addressing the whole plant Lean transformation. The two pilot projects selected were 2500T press TPM and finishing line 3.

TXM assisted 2500T press TPM project team members to identify abnormalities of the pilot machine, establishing focused improvement teams which tackled equipment frequent issues. A Tee cards system was established to manage operators’ daily autonomous maintenance activities.

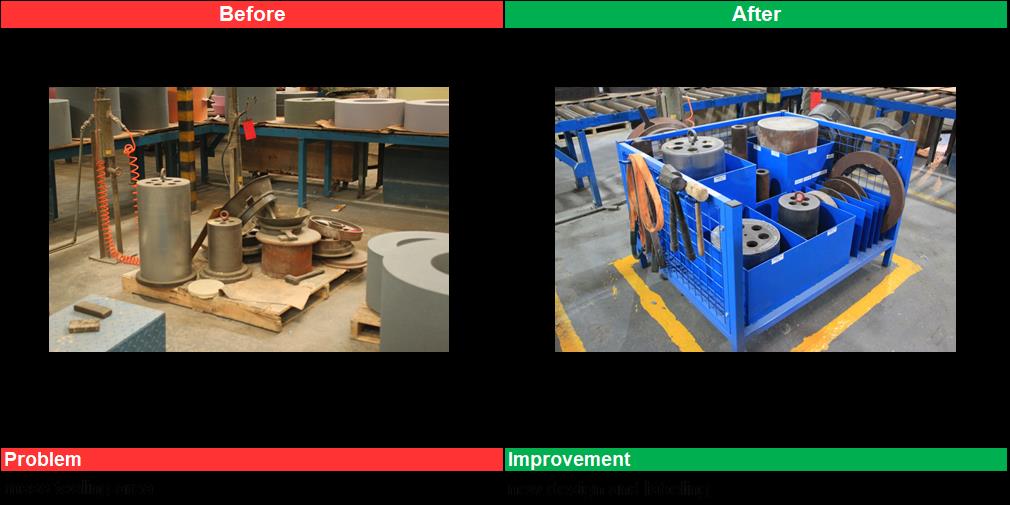

Finishing line 3 projects started with 5S. After good habits were established using 5S, then TXM introduced continuous flow and FIFO (First in first out) to make the products flow through the line.

After the two pilot projects were completed, TXM assisted our client to develop VSM future state map and a A3 action plan to achieve it. The methodology used entailed applying TXM MAP (Manufacturing Agility Process) to improve overall production flow.

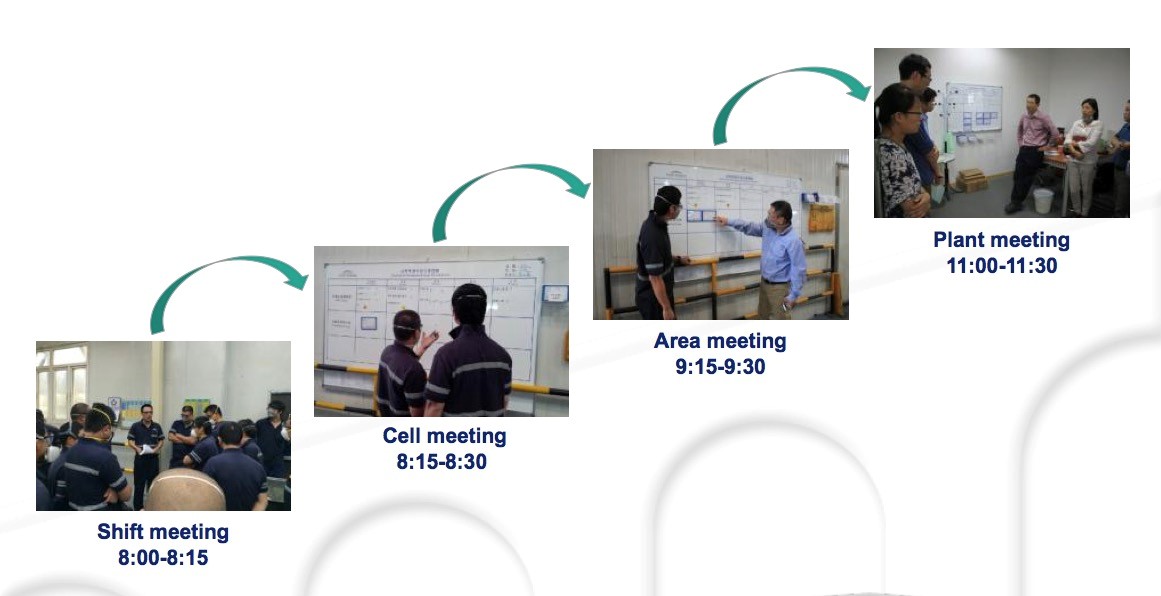

TXM also coached our client using TXM LDLP (Lean Daily Leadership Process) to create a Lean culture in Our client. This included using visual management boards, Leaders standard work and Lean daily meetings

The Results

After one year of working with our client the Shanghai plant achieved breakthrough achievements, including:

- Reducing manufacturing lead time from 14.6 days to 10.8 days;

- Reducing inventory by RMB 1.3 million;

- Improving OTD (On time delivery) by 34.1%;

- Increasing efficiency by 10.7%;

- Reducing defects by 41.5%.