How Do You Reduce Lead Time in Your Supply Chain?

A few years ago I had to decorate a new house. We went to a well-known furniture store and chose a couple of sofas and a coffee table. We then asked the question “When will we get it?”

I was rather stunned to be told that the standard lead time for these items (which were on display in the store) was 16 weeks. “Sixteen weeks!”, I said. “You must be kidding! Where are they coming from? Mars?” “Well actually, they come from China”, the weary shop assistant told me. “China, but it only takes a little over two weeks for goods to come on a ship from China, so what is happening in the other fourteen weeks?”

This rather cheeky question got a blank response from the shop assistant, who simply told me that 16 weeks was the average lead time if I wanted my sofa.

So, I gritted my teeth and waited for what turned out to be 24 weeks before the sofa finally arrived.

This little personal case study sounds extreme, but it is not. I constantly find companies quoting lead times even longer. In one case a European safety footwear distributor was dealing with a 26-week lead time from suppliers in China, while in another an Australian manufacturer was waiting over six months for a chemical product sourced from Italy.

Very few companies I meet would see anything abnormal about a raw material lead time of 12 weeks or more when the goods were coming from the other side of the world from current suppliers.

TXM Article: What is Lean Supply Chain Management

What is Lead Time in Supply Chain?

Apart from my obvious frustration at my 16-week wait for a sofa that became 24 weeks, what does it really matter if average lead times are long? Surely you simply need to allow for the lead time that your customer demand and supplier needs by ordering earlier. Perhaps your customers just need to forecast better! In fact, lead time is the single biggest factor influencing the performance of your supply chain.

A longer lead time means that you will have to carry more inventory AND suffer an increased risk of shortage. Longer lead times make it harder to introduce new products or respond to market changes because you have so much inventory in the supply chain pipeline at any one time.

It also increases the consequence of any quality problem as by the time the problem is found you may have weeks or months of stock already on the way from your supplier and sitting in inventory.

Finally, just to compound the problem, the accuracy of any sales forecast decreases the further into the future you need to forecast. Therefore, the longer the purchase order lead time, the greater the chance that what you order will not be what your customer wants when it finally arrives.

Why is the Lead Time So Long?

All these problems with long lead time delays and times, but as “everyone” knows there is not much you can do about it is there? Wrong!

There is a lot you can do about your long lead times, but before you can reduce the lead time you need to understand what makes it up. The first and most obvious thing to do is to really question why you are sourcing your materials from so far away. The economics of sourcing has changed dramatically in recent years as Asian wages, costs and currencies have surged.

While outsourcing your products may have looked like an economic “no brainer” five years ago, there is a good chance that picture will have changed – especially when you consider the total supply chain cost associated with the long lead time.

However, perhaps you simply cannot afford to bring production back home (reshoring as its commonly known).

So, how do you calculate lead time? The reality is that the actual time to ship goods from one warehouse space or part of the world to another is relatively short compared to the lead times that most suppliers impose.

The table below from my forthcoming book shows the actual shipping lead times for a range of common routes:

Shipping Lead Times Table Example

| Departure Port | Arrival Port | Loading Time | Shipping Time | Unloading and Clearance Time | Total Lead time |

| Shanghai | Melbourne | 2 days | 13 days | 3 days | 18 days |

| Shanghai | Hamburg | 2 days | 25 days | 3 days | 30 days |

| Shanghai | Los Angeles | 2 days | 13 days | 3 days | 18 days |

| Rotterdam | Melbourne | 2 days | 37 days | 3 days | 42 days |

| Felixstowe | Singapore | 2 days | 21 days | 3 days | 26 days |

Figure 1 – Example of Shipping Lead times for common routes from “On Time In Full: Achieving Perfect Delivery with Lean Thinking in Supply Chain, Purchasing and Production Planning”

Why Measuring Lead Times is Important

As you can see the longest lead time including shipping disruptions and port delays is around seven weeks and most lead times from Asia are between two and four weeks. Therefore, shipping time does not explain the excessively long lead times that many supplier demands.

So where does all the entire lead time go?

The answer is that there are many sources of unnecessary lead time. Some of these include:

-

Delays in order processing in your business, particularly when purchasing staff lock themselves in to long ordering cycles such as quarterly ordering or try to accumulate large orders to get a lower price.

-

Delays in order processing by your supplier.

-

Suppliers waiting to receive your order before they order materials. This doubles up the lead time as you now wait longer for your supplier’s supplier to deliver before your job can even get started.

-

Poor capacity management by suppliers.

-

Decision making to give your product a low priority – this can occur for all sorts of reasons.

-

Poor internal processes at the supplier leading to long internal lead time (in other words your supplier needs to apply Lean Thinking)

-

Delays from completion of the goods to shipping (waiting for the goods to be received into the supplier’s warehouse, waiting for freight to be arranged.)

-

Delays at the freight forwarder or at the port waiting for a ship to be booked.

-

Delays due to the use of non-direct shipping routes where ships stop at multiple ports and goods are even cross-docked from one ship to another in intermediate ports.

-

Delays at the receiving port waiting for clearance, cross-docking or shipping.

Some of these issues can add a few days to procurement time, and some can add weeks. Add them all together and you rapidly find the reasons for your excessive lead times. What is important about these delays is that in Lean terms they are all waste and they are all unavoidable.

How To Reduce Long Lead Times in the Supply Chain?

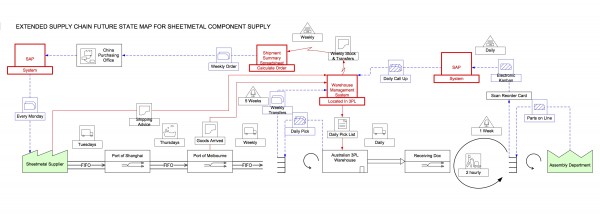

The key to understanding and reducing your lead time is a supply chain value stream map. Typically value stream maps only consider the entire process within one facility.

An extended supply chain value stream map maps the flow of products from your supplier, and perhaps even from their supplier all the way through the supply chain to your business. It may also go further and extend through your business to your customers.

By considering the whole product and information flow the supply chain value stream map will give you a clear understanding of what makes up the lead time. You can then develop a future state map to start to reduce lead time. You will need to involve your supplier in this process but take a collaborative approach.

The goal is to reduce lead time and make things easier for everyone, not to enforce your will on your supplier. Start by looking at the information flow from you to the supplier and the product flow from the supplier to you. As you build trust then you may then be able to start drilling down more into your supplier’s internal processes.

My new book, “On Time In Full: Achieving Perfect Delivery with Lean Thinking in Purchasing Supply Chain and Production Planning” will help you find ways to reduce lead time in your international supply chain. It also will help you address the other problems that make it hard for your business to deliver to customers what they need on time and in full.

Common Questions About Supply Chain Lead Times

Why Can Manufacturing Lead Times Sometimes Be So Long?

Manufacturing lead times can be long due to complexities in the production process.

This includes material sourcing, manufacturing company equipment downtime, labour availability, and the time required to convert raw materials into a finished product.

Longer lead time management of times can also be a consequence of quality assurance measures.

What Are the Different Types of Lead Time?

There are several types of lead time in supply chain management. The production lead time refers to the period processing time required to manufacture a product, including the time for processing, assembly, and testing.

The order lead time, on the other hand, is the period from the order date until it’s ready for delivery. All these contribute to the total lead time in a customer’s order production schedule.

How Can Companies Use Technology to Improve Lead Time?

Technology can significantly improve lead time by streamlining the production time and shipping process.

Digital tools can help lead time calculation, enhance process efficiency, transport costs, minimize human error, and automate labour-intensive tasks.

This not only reduces production cycle time, but also improves the quality of finished products.

What Does Factory Lead Time Mean?

In a broader perspective, factory lead time represents the duration of manufacturing time from the start of production to the time when finished products leave the factory.

Efficient management of factory lead time can improve productivity, reduce costs, and enhance end customer satisfaction by timely delivery.

These key steps help to reduce customer lead time and increase customer satisfaction.

Related Content

Read a Case Study About How to Create a Lean Supply Chain

Learn How a Lean Supply Chain Dramatically Improved Business for Schuetz Australia

Continuous Improvement and Lean methodologies are proven to be effective in reducing Lead Times throughout the Supply Chain. Implementing Continuous Improvement will help to identify and eliminate waste in your processes, resulting in a leaner, more efficient operation. Lean methodologies focus on eliminating waste and maximising value for the customer. By implementing Lean principles throughout your Supply Chain, you can achieve significant reductions in Lead Time. TXM can help you to implement both Continuous Improvement and Lean methodologies to achieve Operational Excellence in your organisation. We have a proven track record of helping our customers achieve sustained superior operational performance. Contact us today to learn more about how we can help you reduce Lead Time in your Supply Chain.