Implementing a Lean Supply Chain

A Lean Supply Chain has the potential to uncover hidden value in your supply chain, eliminating waste, cost and creating greater flexibility to deliver your customers what they want, when they want it.

The Advantages

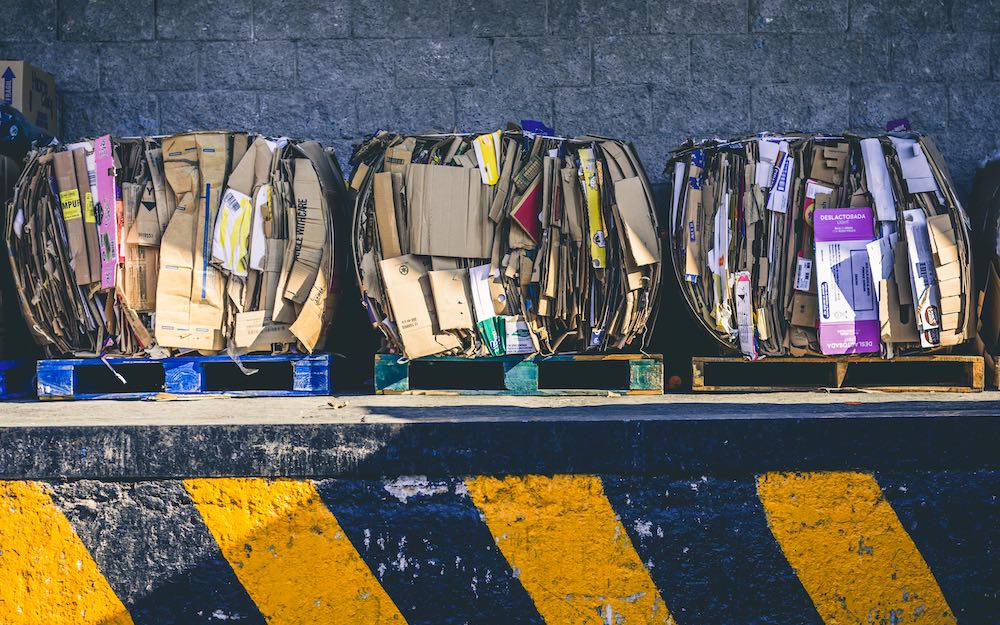

Reducing Waste

Applying the Lean methodology to your supply chain will allow you to see all of the waste occurring at every step of the supply chain giving insight into what you can remove, keep or rework into a Lean Supply Chain. Waste occurs at every step of the supply chain and usually appears in the form of as excess inventory, long lead times, lost productivity, waiting times and product losses.

Traditional supply chain processes focus on compliance and data. A key focus is on making the best use of lean supply chain management information systems such as Enterprise Resource Planning (ERP) systems. As a result, many businesses focus on improving the accuracy of forecasts and ensuring that data in the “master production schedule” such as lead times, lot sizes and set up times accurately reflect reality.

With Lean thinking compliance and control also matters – standardisation is the mantra. However, the Lean approach also challenges the underlying parameters of your supply chain, driving lead times, lot sizes, set up times down at every step in the process. In many cases the Lean solution might be to completely eliminate steps in the supply chain, which can lead to breakthrough improvements in supply chain performance and capability.

Streamlining Processes

Value stream mapping is the tool Lean supply chain practitioners use to find all of the hidden waste in the supply chain. This enables streamlining of processes across the whole supply chain from the supplier through manufacturing and distribution to the end user. Streamlining processes and discarding non-value-added activities it will boost productivity and increases profits.

Engaging and Developing People

Respect for people is a core principle in Lean thinking. In Lean supply chains this extends to all the people involved in the supply chain including suppliers and outsourced service providers. Traditionally supply chain management focuses on analytics and data. In Lean data is important too, but the data is backed up by real world observation, rather than analysis from a computer terminal in a CBD office.

Lean leaders go to the place where the work is done to see what the real situation is, they then ask why when things are not to standard and they show respect by listening and understanding their world. In the Lean supply chain this means going to suppliers, to the warehouse and to customers to “go see, ask why and show respect”.

The Challenges

Although the advantages of a Lean Supply Chain are clear there are challenges and barriers that need to be overcome. These challenges include:

Leadership

Supply chains are often cross functional, which can make achieving change difficult if one functional link in the chain is not aligned with the change. For example, in some well-known businesses, Lean supply chain efforts have been unsuccessful because the procurement team have focused on reducing unit cost as a goal above all others.

This often leads to frequent changes of suppliers, adversarial relationships and the selection of suppliers who lack the skills and capabilities to collaborate in a Lean supply chain (but have really low unit price). Much of the “low-cost sourcing” wave of the past 20 years has been driven by this kind of logic but has not necessarily left businesses better off overall.

The behaviour of procurement managers is driven by the goals and metrics they are set by C-Suite executives. Therefore, alignment is needed at the very top about the need for a Lean supply chain if it is really to translate into sustainable results.

Culture

While many may see the supply chain as a highly technical and data driven field it is in fact awash in “common knowledge” and entrenched assumptions. Some typical beliefs I come across are:

- “the solution to our supply chain problems is a more accurate forecast” – your forecast will never by accurate enough.

- “the computer will give a better answer” – the computer’s answer is only as good as the data that goes in and often the raw data and underlying assumptions input into an ERP system are wrong and so the recommendations of the systems will also be wrong.

- “technology solutions are better” – supply chain management seems to be a magnet for software providers and therefore many supply chain leaders assume that the solution to any problem will be more software, a better model or more reports. However often more technology just adds more confusion. Look for the simplest solution that gives the result you need and avoid being overly perfectionistic.

- “sourcing from Asia is cheaper” – for many products it is, but total cost needs to be considered, not just unit price.

Changing these cultural assumptions and others like them requires firstly identifying and defining them. Then you need to demonstrate that a different approach works better. This might be through a pilot project or through modelling to show how a different approach delivers different outcomes. When you can demonstrate that the Lean supply chain approach delivers better overall results, you can then challenge the underlying assumptions and beliefs that underpin the traditional approach and people’s behaviour and decision making will change.

Knowhow

Lots of people claim to know Lean. Many ERP providers will argue that their forecast driven “push” planning tool is “Lean” because it offers “min-max” replenishment capability. However, Lean is not a single tool or software module, it is a complete management system. To understand Lean you need to find people who genuinely understand Lean supply chain principles.

Look for experts or advisors who have practical experience of Lean supply chains and can share case studies and references from real projects. Do your own research by reading Lean books so that you can check whether the experts you are talking to really understand Lean supply chain or are just trying to jump on the bandwagon. TXM Director, Tim McLean has his own book on Lean supply chain and this can be a great place to start.

At TXM we are passionate about Lean Supply Chain. Our team brings together decades of experience over hundreds of successful projects. So if you are looking for a new approach to your supply chain that will deliver lower costs, lower inventory and better delivery performance, talk to us now.