How to Bring Your Production Back Home

I recently made the business case for re-shoring production. However, once you have made the decision to bring production back home, how do you go about carrying it out?

Step 1 – Start with Your Customers

The design of your supply chain needs to align with the current and expected future needs of your customers and your strategy. This was a mistake that many businesses made during the offshoring process. They treated off shoring as purely a purchasing decision and created inflexible extended supply chains that were simply incapable of delivering what customers needed.

The result was high inventory, expediting and lost sales. Therefore, avoid making the same mistake twice by taking a clear-eyed look at your market, analysing your customers and competitors and deciding where you want position your business. What is the performance your customers expect in terms of lead time and on time delivery? Beyond that though, what would be the benefit of being to offer better service and shorter lead times? It can also be good to see what the best performers in your market internationally are doing, even if you are not competing directly with these companies.

Step 2 – Understand the End to End Supply Chain

Once you have decided the service that you need to deliver to customers, then the next step is to design your supply chain from the ground up to deliver that service – reliably, on time in full every time.

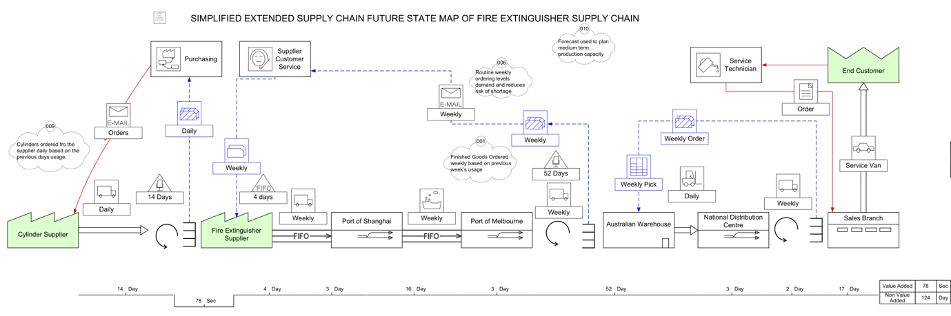

Map Your Current Value Stream

Start by mapping your current extended supply chain. We use an extended supply chain value stream map to do this. The current state map will show both the product and information flow for your offshore supply chain. The boundaries of the future state need to at least start with inputs to your supplier and end with delivery to your customers.

However, you may even need to go further upstream than that and consider your suppliers’ supplier. This can be important if the real value add happens up stream in the supply chain or if supply of critical raw materials is likely to influence the location of production. Apart from lead time and inventory, overlaying metrics such as cost and quality on the value stream can also show a clearer picture of what your offshore supply chain is delivering, or not.

Once you have mapped the current state, you will have a good idea of whether your current supply chain can meet your current and future customer needs. You should know the key risks and costs and how and why they arise through the supply chain.

Developing Your Future State

The next step is to develop your future state. This starts with clearly defining your customer needs and working backwards. At TXM we ask a number of questions to take you logically from the current state to your future state. In a re-shoring situation it might be necessary to consider a range of future state options and then model these for cost and feasibility. It can be useful to start with an “ideal” future state, which is the one closest to one-piece flow and which most effectively delivers your customer’s needs. This may not end up being a feasible option, however it allows you to evaluate each of the options against the ideal. It also opens you up to more ambitious change rather than just incremental changes from the status quo.

If you build a cost model to compare options, make sure you model costs such as working capital holding costs, warehouse costs, stock obsolescence, quality costs and costs of supporting international suppliers. You should also make some assumptions of relative inflation and currency movements. Often major projects are evaluated using “current day” values, but with international sourcing, the products are being manufactured in one economy and consumed in another. Changes in relative inflation and currency can actually be the biggest influences on total costs over time, so they cannot be ignored. Qualitative factors such as protection of core intellectual property and risk of supply disruption also need to be considered in the equation.

If your product has a short life-cycle, then the development lead time can be an even more important factor than the supply lead time and so it may pay to map this as well as a separate exercise.

Step 3 – Make or Buy

Once you have mapped your supply chain and considered the various options, you will have identified which parts of your supply chain it makes sense to move back on shore and which will remain sourced overseas. However, don’t assume that it is simply a matter of finding local suppliers to replace your offshore suppliers. This may not be the best option. Over the past five years, we have seen an increasing trend for businesses to vertically integrate. Therefore, rather than moving from an offshore to an onshore supplier, these businesses are moving production from offshore suppliers back into their own factories. There are several reasons for this:

- Vertical Integration – Means that the profit margins being made by your suppliers on products being manufactured for you become your profit margins.

- Producing In-house – Can enable you to create highly flexible dedicated “cells” focused on key value streams in your business. Often the flexibility benefits gained from bringing a process in house can justify the investment, even if the utilisation of the new machine or process is quite low. For this reason, it is important to evaluate the costs and benefits for the whole value stream rather than process by process.

- Advances In Technology – mean that less specialised expertise is needed to take processes such as machining, circuit board manufacturing or sheet metal fabrication in house. Machines are more automated and intuitive making them simpler for less skilled staff to program and operate. As well machines are generally cheaper, and in many cases occupy smaller footprints reducing the capital demands.

Your “Ideal” future state will aim to minimise lead time and waste, so will tend to encourage bringing processes in house. Where this is not feasible, then you can capture the costs and benefits of moving to an external supplier. Key reasons to outsource might be:

- Your volumes and spend do not justify developing the in-house capability.

- The capital cost or technical barriers to set up the in-house capability are too great.

- Environmental or location related issues (e.g. with electroplating).

However, having decided to source a local supplier, it is important that you end up with a better service level than your current, offshore supplier. This is not guaranteed. Selecting the wrong supplier can potentially mean you end up with higher costs, poorer quality and no appreciable improvement in lead time or flexibility. Therefore, it is important that you have a well thought out supplier selection process.

Step 4 – Selecting a Local Supplier

The purpose of on-shoring your supply chain is to improve your supply chain responsiveness and flexibility. Your choice of local suppliers will determine how you achieve that. This needs a holistic approach, not one just focused on unit cost. If you have done a value stream map, this will provide you with a clear idea of how you want your local supply chain to operate. Measures such as the lead time, order quantities and quality parameters will be determined by the value stream map.

Start by identifying potential suppliers and discussing their capabilities. If the products you will be purchasing represent a significant value, then it is worth doing a competitive bid process. There is no requirement for this to be a formal tender and in fact a fair, but more informal process can be more effective. Meet with as many suppliers as you can, visit their premises if possible and understand their capabilities and culture. You can then apply some criteria to identify the few suppliers who are best suited to meet your needs.

Once you have your short list then develop a detailed bid document, or request for proposal. This needs to specify exactly how you want to the supply chain to work and what you need suppliers to deliver. The advantage of specifying these operational elements up front is that suppliers know from the start exactly what they are up for and are less likely to try and renegotiate pricing later. Finally, before the bids come in, you need to agree within your business selection criteria to choose suppliers to avoid the decision just being made on price. Total cost of ownership needs to be considered.

Your request for proposal document then provides the basis for a service level agreement with the selected supplier and metrics to track supplier (and your) performance against that agreement.

Setting up supplier relationships this way means that your new suppliers are aligned to your business needs from the start, delivering the level of service required in your value stream.

Step 5 – Implementing the Change

Start with a Plan

Changing your supply chain is a complex and risky task. The length of your overseas supply chain means that the change is likely to occur over months. This brings the risk of both obsolete product and of interruptions to supply. You therefore need to start with a plan. This plan should cover the time for local suppliers to get set up (or for you to tool up internally) as well as the time to build up stock from your new supply chain and rundown stock for the old supplier.

It is good to define a break point to ensure traceability of which parts went into which end products in case a quality issue occurs down the track. If the supply chain change coincides with a new model launch (as it often does), then it is important that you communicate clearly to your sales and marketing team about the timing of the change over to the new model so that you do not end up with excess stock of the old model or a supply gap for the new model (or both). For most offshore supply chains this is likely to be a six month transition, so a lot of discipline is required.

Plan Your Transition

While we all hope that our outgoing suppliers will act honourably and support you through the transition, this is not guaranteed. Our advice would be to get your prospective local suppliers (and if necessary, staff and external advisors) to sign confidentiality agreements before you engage them in the bid process so that you can control how and when the change is communicated with your overseas supplier. Otherwise your overseas supplier may decide that it suits them to end supply to you early, which may create a gap in supply.

You need to honour all agreements with your existing supplier and provide them with fair notice so that they do not end up with obsolete raw materials of their own. Some overseas suppliers may try and argue that you have to cover the costs of their excessive stock levels of raw materials and work in progress. Having a good service level agreement with these suppliers that defines in advance the stock you will pay for is important to avoid this situation. These considerations aside, you should ensure that your new supply chain is up and running and ready to go before you notify the outgoing supplier. Again, this may extend your transition further, but the alternative is to run the risk of stopping supply to customers.

Step 6 – Get Lean!

One of the most heart-breaking elements of the off shoring craze of the past decade has been the number of products I have seen sent off shore unnecessarily. Rather than try and improve an inefficient manufacturing operation or turn around a poor culture, it seemed simpler to just close the factory and give production to an offshore supplier. However, there is no free lunch in business and many of these companies found themselves actually worse off with high working capital, inflexible supply and quality problems galore. As well the overseas suppliers often used the opportunity to learn about the market and start supplying in their own right. Therefore, companies often created their own competitors. A bit more effort to improve their local manufacturing with some Lean thinking could have avoided all these problems.

When you bring production back, take the time to get it right. Your value stream map (Step 2) will have shown you the way, but it is important that you follow through to build a Lean production system if you are bringing production in-house and a Lean supply chain to connect to your suppliers. The aim should always be to minimise lead time and maximise flexibility. If you are measuring the lead time your local supply chain in weeks, not days, then you have probably not done enough to really leverage the benefits of being local. So double down on your Lean efforts to create a system that can deliver you a real competitive advantage with your customers.

Summary

Transitioning your supply chain closer to home is a change that we will see a lot of over the next few years. However, it is important to plan carefully when making this change to ensure that it actually delivers the benefits you expect. Start by being clear what you need to deliver to your customers. Then design your new supply chain using an extended supply chain value stream map. Consider the option of vertical integration – bringing production in-house to get maximum flexibility.

If you are going to switch to local suppliers take the time to conduct a proper selection process to ensure that you will achieve the supply chain performance improvement you want. Once you have decided on how you will structure your supply chain, plan carefully to allow for a smooth transition from imports to your new, local supply chain to avoid creating obsolete inventory or interruptions to customer supply. Finally, use Lean thinking in your new manufacturing and supply chain to bring your lead time down from weeks to days. This will ensure that you deliver substantially better service and create a competitive advantage from being local.