How to Lead a Lean Transformation

What makes some companies successful at implementing Lean while others struggle to make any progress?

The answer you will get from most Lean experts is “Senior Leadership”. But what does this actually mean?

A failure of leadership is the reason for the failure of most business change programs, not just Lean. So, what leadership approaches are important specifically for Lean implementation?

Lean is Not a Strategy

I often hear managers tell me that their strategy is to implement Lean. My response to this comment is “Why?” Lean implementation needs to be driven by a clear strategic goal. Lean may provide the means to achieve that goal, be it to reduce lead time, increase agility or reduce costs, but some companies will state that “implementing Lean” is their strategy. If Lean is the strategy then how is success measured?

Usually, by measuring the extent of the roll-out, the number of people trained, the number of projects, this may or may not relate closely to the overall business objectives. However if Lean is driven by a strategic goal, then success will be measured by the achievement of that goal.

There is No Use Having a Strategy if No One Knows About It

I recently reviewed the excellent business strategy of a major company. Unfortunately, discussions with middle managers revealed that few were aware of it and the strategy certainly wasn’t driving action in the business. Once you have decided on the strategic goals then you need to communicate it.

The Lean policy deployment process (Hoshin Kanri) using the A3 plan is a very effective way to cascade the strategy through your organisation and ensure alignment. It is important to realise that Hoshin Kanri and A3 planning is a process and a way of thinking, not just a report template.

Walking the Talk – Leader Standard Work

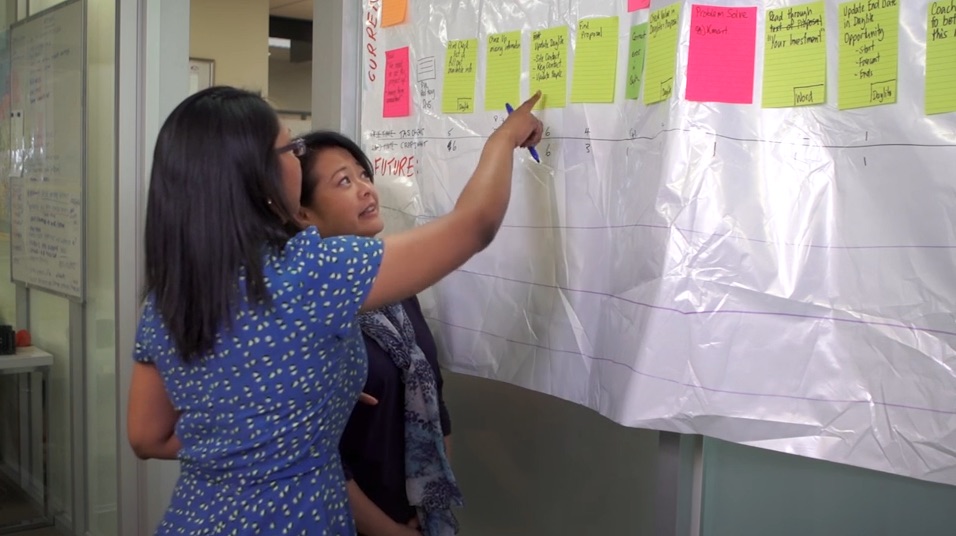

Successful implementation of lean requires cultural change and culture only changes when leaders demonstrate the change through their own actions. This means practical behaviour change in everyday interactions with your team. Standardising routine leadership tasks helps build good habits and ensures a consistent approach by leaders. With leader standard work the aim is not to set a fixed schedule for every leader every day, but rather to set a few fixed events e.g. regular standup meetings and a list of routine tasks that must be completed regularly.

These can include regular walks through the workplace, checking key metrics or processes, and carrying out key process audits such as 5S audits. The daily standup meeting is a critical event at every level of the organisation. This should occur at a fixed time every day, be carried out in or near the workplace, and be limited in time (usually no more than 15 minutes).

Standing up reduces the tendency for everyone to get too comfortable. The meeting provides an opportunity to quickly review yesterday’s performance, discuss the issues for the coming day, and solve problems. It can help to have a standard agenda or checklist to follow on these meetings – just don’t make it too long and avoid loading it with issues that don’t directly relate to delivering value to the customer (although you may want to include safety). In terms of the daily leader tasks, a red-green task board (or Kamishbai board) can help leaders remember the tasks they need to complete each day and the coloured cards provide great visual controls.

Mind Your Language

Lean is a way of thinking and language is important. A key starting point is behaviour when things go wrong. Make sure that, as a leader, you are asking why the problem occurred, rather than just focusing on who is at fault. Problems should be an opportunity to apply problem-solving techniques and learn about the process. Resist the temptation to apply a quick fix, get the process going, and move on to the next problem. Taking the time to solve the problem and address the root cause will take longer in the short term, but will mean the problem should not return – saving time in the long term.

Feedback

Feedback is also vital to all of us, so when your team is measuring performance it is essential that you notice and comment on the performance – praising good performance and asking “why?” when performance fails to meet targets. Likewise, visual controls are designed to communicate abnormalities in the workplace and inform decision making. If you fail to notice the abnormal situation or fail to take the standard decision (or worse – you over-ride the standard decision) then expect the visual controls to fail. An example might be a first in first out lane. In one client we had a manager who constantly pushed jobs in the front of the queue and also refused to stop production upstream of the lane when the lane was full. He said that he was committed to FIFO, but his actions sent a different message. As a result, the FIFO lane did not work until his leadership behaviours changed.

Conclusion

As a former manufacturing leader, I know it is not easy to meet all the expectations placed on you. Perfection in leadership is neither necessary or achievable – you don’t need to be Winston Churchill or Nelson Mandela to manage a factory or a department within a factory. However, there are some disciplines you need to apply to yourself in order to achieve Lean success. They are not complex, but they need to be followed constantly and consistently.