Client Prime Fluid Management

Location New Zealand

Prime Fluid Management Boosts Operational Efficiency and Quality

Background

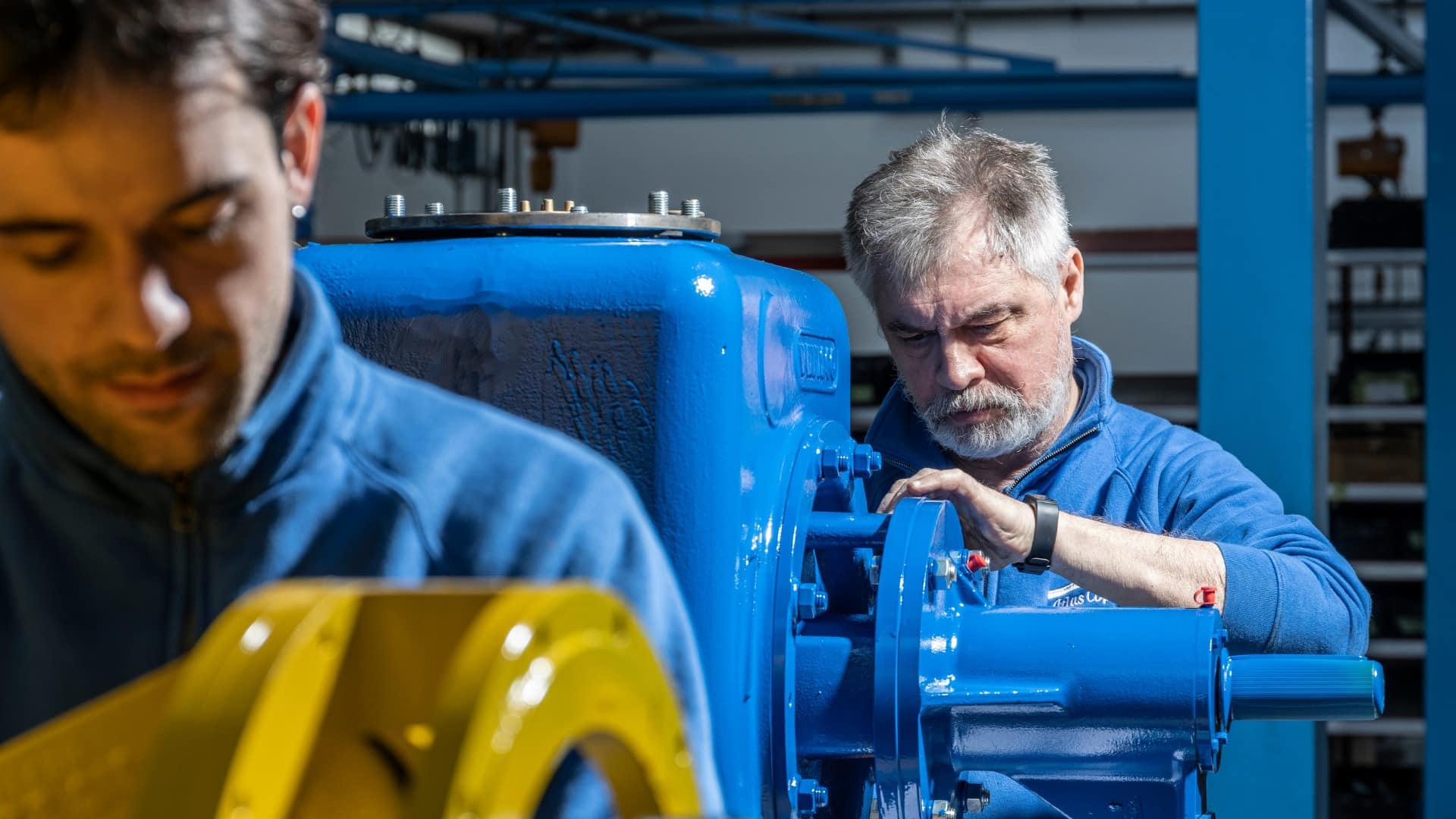

Prime Fluid Management (formerly Prime Pump) are a successful and growing family-owned business suppling pumps, pump sets, pump hire as well as workshop & field servicing. The business is based in Greymouth with an additional 4 sites across New Zealand.

Prime Fluid Management supply pumping equipment to civil & mining, construction, agriculture, industrial applications, and food & beverage. They have seen steady growth over the past 7 years and were looking at streamlining operations with better standards. The team at Prime Fluid Management contacted TXM Lean Solutions New Zealand to help identify, analyse, and devise solutions to their growing pains.

The Challenge

Prime Fluid has been steadily growing with a strong customer base and growing demand. They are strategically positioned in the market, but several processes remain underdeveloped. Senior business leaders highlighted various concerns that need attention, including quality issues, staff training, and the establishment of standardised work instructions. The senior business leaders recognise considerable opportunities to improve current processes including adoption of visual management, better 5S practices and increased quality consistency through standardisation.

The Solution

Senior Consultant Darran Allen was tasked with helping Prime Fluid overcome their operational challenges at their Greymouth site. He started a review of the end-to-end process from order receipt through to dispatch with the goal of increasing productivity, reducing quality errors and increasing capacity to handle a higher volume of orders. Review and streamlining the warehouse layout and processes has enabled Prime Fluid Management to make better use of the space whilst processing more orders with the existing team.

Developing standardised systems to manage inventory and replenishment in the warehouse will help minimise stock duplication and reduce freight costs. This will also enhance visibility and provide real-time job status updates, allowing issues to be identified and addressed more proactively. Darran engaged key personnel at Prime Fluid to design and implement these systems ensuring that Prime Fluid Management can grow and prosper into the future..

The Results

The team at Prime Fluid Management were able to transform the operations with amazing results:

- Increased throughput in the workshop by 25%

- Capacity improvements have freed up resources

- Along with improvements in accuracy, visibility and quality

- Increased consumable recoveries by 63% in 12 months