Managing operations is hard, sometimes thankless work. Competitive pressure, employee demands, rising costs and demanding customers can make the achievement of reasonable returns seem impossible.

Faced with these complex challenges it is normal to look for a simple solution. A single idea, decision or well-chosen investment that can change the paradigm and deliver the business to a promised land of higher returns and all-round superior performance.

In other words, the elusive “silver bullet”

And there are no shortage of people offering that silver bullet.

Whether it is software providers, automation suppliers or consultants offering a new management system, operations leaders are constantly approached by people promising to solve their problems by simply buying their solution.

Operational Performance Improvement: The Silver Bullets?

Software

The most common purveyors of “Silver Bullets” are software providers.

Barely a day goes by where I do not come across a new provider offering a new software product that they claim will transform business.

AI

The artificial intelligence boom seems to have turbocharged this effort with most solutions now augmented by AI which is promised to offer almost magical results.

Software is an essential tool for any business, and every business leader should be aware of the tools that are available for their business, including the application of AI. However, on its own, software is never the answer to your business’ problems.

As I like to tell people, the role of software is to automate processes, but software rarely fixes processes. Implementing software in an environment where your core processes are not well understood and/or there is poor discipline in following those processes will generally increase confusion and make the underlying problems worse.

Garbage In, Garbage Out (GIGO)

A key argument for software is that integrated systems provide better visibility about what is happening within the business. However, this is only true if the data the software is collecting is timely and accurate (the adage of “garbage in, garbage out applies”). Even if the data is accurate, then the information provided is only useful if it leads to action.

Therefore, software is often part of the solution to improving operational performance but is never the whole solution.

Automation

Another popular “silver bullet” is process automation. Automated processes should be more predictable, consistent and cost less to run due to reduced requirement for labour. However, automation comes at a price.

Cost

This price is measured in increased fixed capital that your business must finance and increased operating complexity. Many operational leaders develop grandiose plans for the fully automated factory or warehouse.

The result is usually disappointment as complex projects are delivered late, over budget and fail to deliver the expected benefits. In the most complex implementations, the challenges getting the various automated machines to work together effectively can be insurmountable.

Employee Performance

The performance of the automation is limited by its weakest and most unreliable link. As well, staff, used to manual processes, often struggle to adapt to the skills needed to operate automated equipment. Finally, the additional technical and maintenance support needed to keep the equipment running is often overlooked.

Once again, the adaptation of new process technology is an essential element of keeping your factory up to date.

However, seeing automation as a panacea has lead to costly mistakes. In particular, the cost savings and competitive advantage that automated equipment gives often lasts only as long as it takes for competitors to catch up and invest in similar equipment.

Training And Off The Shelf Consultant Programs

So, if software and automation are not the silver bullets to turn around manufacturing performance, then perhaps a Lean or Six Sigma program might be.

Lean Six Sigma

In the spirit of silver bullet searching, this might mean implementing an across the board Lean Six Sigma training program to make sure everyone in the business has the skills to improve performance.

Unfortunately, this approach also leads to costly disappointment. There is a big step from having skills and knowledge to using those skills and knowledge. Most companies who have engaged in this kind of mass training (or “sheep dipping” as we call it) see little return on their investment in staff time.

This not to say that training isn’t useful, but it is more a complement to driving improvement, than a solution.

Off The Shelf System (Lean By Numbers)

Another approach is to buy an off the shelf improvement “system”. There are several of these promoted by large leading consulting firms. I call them “Lean by numbers” in that they lay out a very structured and usually well thought out step by step process to implement a continuous improvement program. These systems are also costly but can deliver some improvement.

However, this improvement is rarely sustained because ultimately the system is the consultant’s system not your system and will never be an exact fit to the needs and culture of your business. They also tend to set “being Lean” as an end rather than focusing on the specific improvements that the business needs to make.

Training

Mass training and off the shelf programs can be useful and can help achieve some short term change, but like software and automation will not lead to the sustained underlying improvement that your business needs.

So, What Is The Silver Bullet?

The answer, as you might expect, is that there is no silver bullet.

Achieving sustainable operational performance improvement is a complex, multifaceted challenge requiring a range of tools and strategies working together to deliver results.

Some of the key factors for achieving this change are the following:

The Need For Change

Having a clear strategic need for change. When everyone can see how the improvement effort connects to the overall business strategy and vision it is much easier to motivate people to commit time and resources to ensuring its success.

People need to know why the change is essential.

Leadership

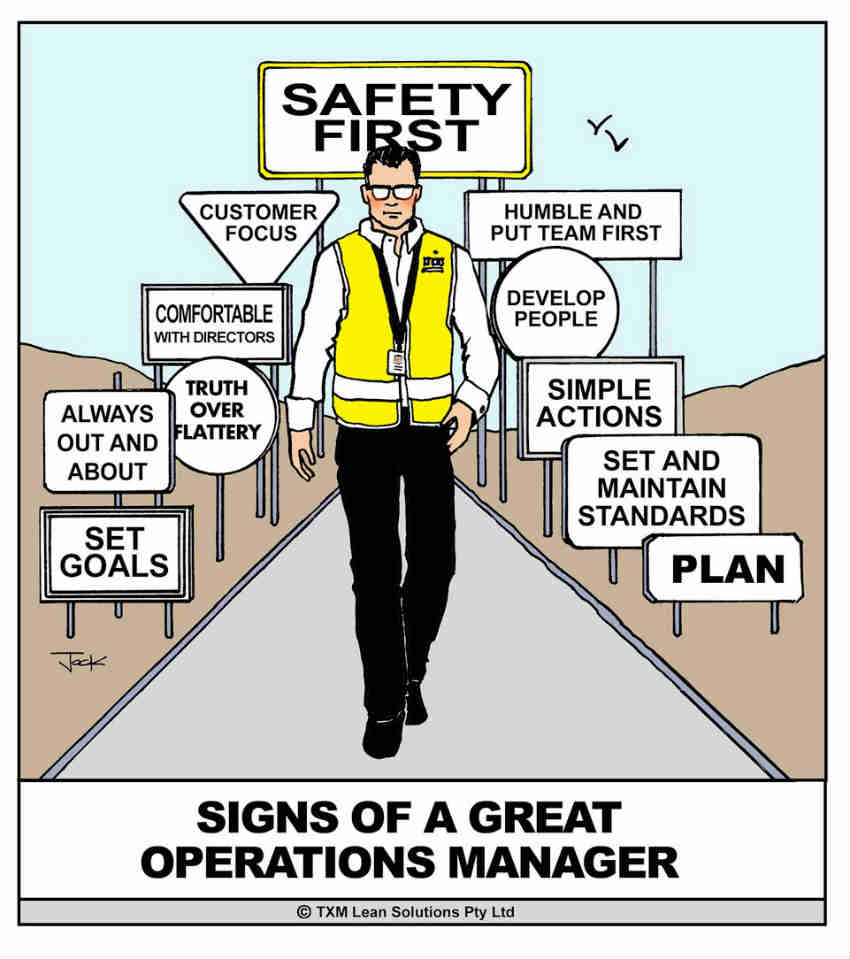

Leaders aligned on the need for change.

The old saying “the standard you walk past is the standard you accept”. Team members are highly sensitive to leaders saying one thing and doing the opposite and therefore leaders across all functions need to be disciplined to send a clear and consistent message.

Catalysts For Change

Use consultants and external resources as suppliers of knowhow are catalysts for change and coaches, never as a substitute for internal resources.

The change must be owned by your people if it is to be sustained.

This mean the bulk of the effort needs to fall to them and not be outsourced to outsiders.

Value Creation

Understand how and where value is created in your business.

Start by asking “what does our customer really want?” and work backwards through your core value stream to ensure that every step in your process is completely focused on delivering that in the most effective way possible.

This may mean targeted investments in software and automation, but it may also mean simple process improvements that cost nothing. Remember “don’t substitute money for brains”.

Metrics

Establish simple and clearly understood metrics through the business that align with the overall strategic goals.

When everyone has a measure to work to, then everyone knows how they are contributing to the success of the business.

Develop Leaders

Focus on developing leaders. Change need to be lead at every level in your business. Leaders need to be provided the skills, motivation, support and accountability to lead that change. This applies to every leader from the CEO to the most junior front line leader.

Resource the change

A key reason why improvement initiatives fail is that businesses fail to provide the right resources.

Just expecting a major change to be achieved on top of “business as usual” is unrealistic. Too often ego gets in the way of leaders asking for help, but equally short-term financial restrictions can undermine the success of long-term change initiatives.

Problems never go away miraculously on day one of a new initiative (unlike a “silver bullet”) and so while improvement is underway workload will increase.

This must be planned for and additional resources allocated if the improvement initiative is to succeed.

Common Questions Around Operational Performance

What Is Operational Performance?

Operational performance refers to the effectiveness and efficiency with which an organization executes its business processes to achieve its goals.

It encompasses various aspects such as productivity, quality, cost management, and delivery speed.

What Are The Key Performance Indicators Of Improved Operational Performance?

Key performance indicators (KPIs) of improved operational performance typically include metrics such as cycle time reduction, increased throughput, improved quality levels, and enhanced resource utilisation.

Other essential KPIs may involve cost efficiency, customer satisfaction scores, and on-time delivery rates.

By tracking these indicators, organizations can gain insights into their operational effectiveness, identify areas for improvement, and drive sustainable growth and competitiveness.

What Is The Connection Between Operational Performance And Customer Satisfaction?

Operational performance directly impacts customer satisfaction by influencing product quality, service delivery, and overall customer experience.

Efficient operations lead to faster delivery times, fewer errors, and consistent quality, all of which contribute to higher customer satisfaction.

Summary

So, sadly, there is no “silver bullet” to overcome your operational challenges and I suggest that you be very wary of anyone who promotes one.

Instead, clear strategy backed up by strong leadership and the right resources is the best formula to deliver sustained operational performance improvement.