Creating a Lean culture, or for that matter creating any positive change, seems very difficult in some organisations. They seem to have a form of entropy where all improvement regresses quickly back to the mediocre normal.

What are the Big Barriers to a Lean Culture?

Observing these companies, we often find four big cultural barriers – complacency, low expectations, learned helplessness, and passive acceptance. Last month we talked about complacency. This is the belief within an organisation that things are already good enough. In complacent cultures leaders and teams believe there is no need to improve. In the worst cases, this is because the leaders believe the business is already the best.

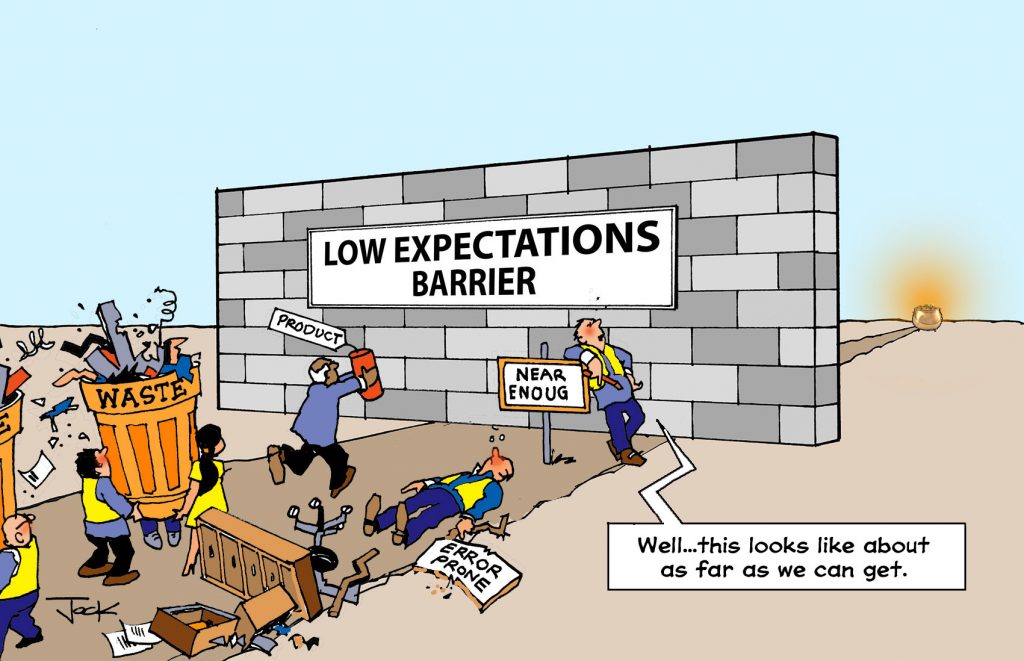

The next cultural barrier we are going to discuss is low expectations. This is the belief that things can’t get better. Unlike complacency, which is usually a by-product of over-confidence, employees in businesses with low expectations often lack confidence in themselves, their leaders and the business.

Learn About How to Overcome Complacency in Your Organisation

Low Expectations

What is It?

Many businesses have low expectations about how much they will every achieve. It is a bit like a football team believing that they will only ever reach the middle of the table and never be champions. Low expectations exist in all sorts of ways through organisations. They can relate to performance, as in the football example, but they can also relate to behaviour and processes. For example, managers may believe that their staff have limited capabilities and can never take responsibility or will always make mistakes. Teams may believe that machines will always break down or “that product always has a lot of waste”.

Low expectations are often reinforced by a belief that standards for parameters such as quality, delivery or cost are unreasonable, backed up by a lack of consequence when the “unreasonable” standards are not met.

Why are Low Expectations a Problem?

Low expectations are never met. The team that aims for the middle of the league table usually finds themselves at the bottom of it. Staff whose leaders have low expectations never demonstrate their true capabilities. And the machine we always expect to break down, does. Low expectations are a powerful barrier to excellent performance, because they dictate that excellent performance is simply not achievable.

Likewise, if we think that standards for quality and delivery are not reasonable, we will never meet them. You create a culture of “near enough is good enough”. This can lead to very negative consequences when the out of specification product you sent, because you thought the specification was unreasonable, causes a major problem for your customer.

Overcoming Low Expectations

The best way to overcome low expectations are to exceed them. Look for little wins and islands of excellence and publish them. I like to encourage companies to find the best they can be – the best month and the best team performance and challenge themselves to match that every month. You can argue that if that if we can achieve that excellent performance once, we can achieve it again. Likewise, if one team can set a record or achieve an excellent performance, another team can too.

You can also overcome low expectations through setting and maintaining standards. Start with little things, such as standards for housekeeping or punctuality. Extend these standards to quality and delivery. Most critically, you as a leader need to enforce the standard. When your team does not meet these standards, you need to discuss this with them. Use a problem solving exercise to understand why the business failed to meet the standard. You need to agree what corrective action is needed to achieve the standard next time. With low expectations “the standard you walk by is the standard you accept”, so as a leader you must be persistent in maintaining the standards you set.

Learn More About Lean Leadership

Read Our Lean Culture Series of Blogs

Overcoming Four Big Barriers to a Lean Culture Part 2: Beating Low Expectations

Overcoming Four Big Barriers to a Lean Culture Part 3: Overcoming Learned Helplessness

Overcoming Four Big Barriers to a Lean Culture Part 4: Stopping Passive Acceptance