How Do You Create a Lean Culture?

Creating a Lean culture, or for that matter creating any positive change, seems very difficult in some organisations. They seem to have a form of entropy where all improvement regresses quickly back to the mediocre normal. Observing these companies, we often find four big cultural barriers:

- Complacency – the belief that things are good enough as they are.

- Low expectations – the belief that things cannot get better.

- Learned helplessness – the belief that people within the business cannot influence change.

- Passive acceptance – the leadership behaviour where leaders ignore non-compliance to standards.

Lean Minute Video – How To Create a Lean Culture By Changing Everyday Behaviours

These four cultural barriers individually or in combination can frustrate your Lean transformation efforts. Unfortunately, they are very common across a wide range of organisations. Over the next few months we are going to discuss each of these four big barriers to a lean culture and how they can be overcome. This month we are starting with the most common of the four big barriers – complacency.

What is a Complacent Culture?

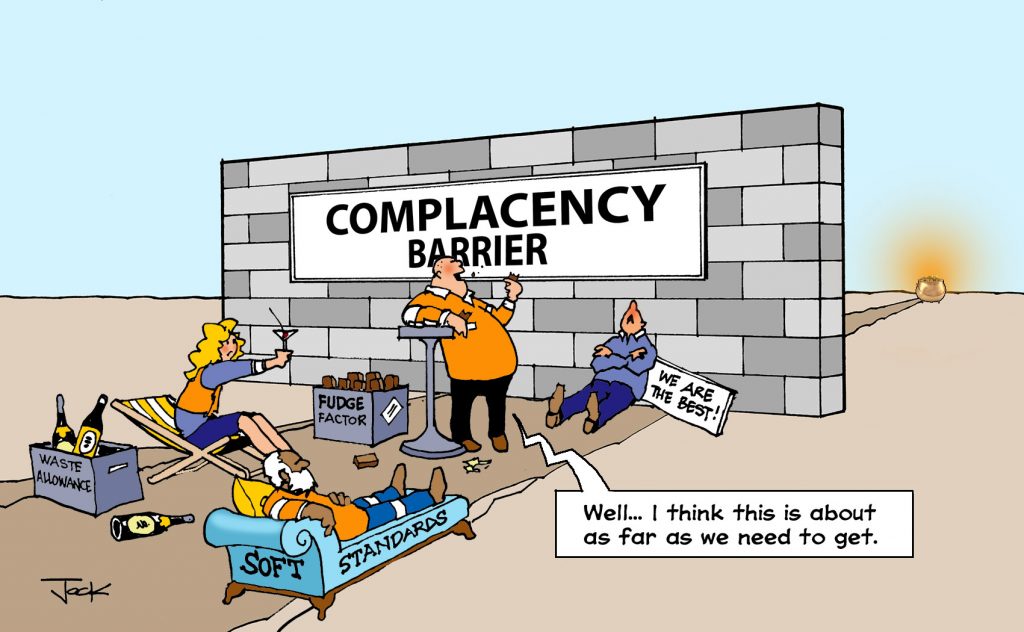

The most easily recognised of the cultural barriers, complacency is simply a belief that things are good enough. In complacent cultures leaders and teams believe there is no need to improve. In the worst cases, this is because the leaders believe the business is already the best.

This is often reinforced by metrics which appear to show that the business is performing well. When businesses tell me that their Overall Equipment Effectiveness is over 95%, waste almost zero and on time in full delivery (OTIF) at 100%, then I am usually sceptical. If these businesses were really that good, that would be a problem, because there genuinely be no need for improvement. However more often, businesses delude themselves by using soft production standards for OEE, generous waste “allowances” in bills of materials to hide waste and by fudging delivery dates for OTIF. This type delusion means that huge improvement opportunities are covered up.

Why is Complacency a Problem?

At a point in time your business may well be the best performer in its market. However, markets change and competitors are always trying to innovate and overtake your business. If you think you are already the best and don’t see room for improvement, chances are you won’t be the best for long. When you do fall behind the competition, the consequences can be devastating as your belief in your own superiority can often lead you to deny the change and delay action.

Overcoming Complacency

Sometimes it does take a market shock to get a business out of complacent thinking. However, that is a costly way to learn. Instead benchmarking can be a good tool. Get an external party to assess your business and compare you to known benchmarks for similar businesses. Go and visit other businesses, perhaps by joining a networking group such as Best Practice Network. A customer survey can also give a jolt of reality.

As a leader coming in to a complacent business, set challenging goals that cannot be met without change. Create a sense of urgency (sometimes called a “burning platform”) that paints a picture of what will go wrong if the business does not improve. Hand in hand with this is the need to get rid of “sand bagging” in the way the business measures itself. Where possible measure performance in absolute terms rather than against standards and flush out “fudge factors” such as “soft standards”, “waste allowances” and “delivery date negotiation”.

Next month we will talk about a related cultural belief, low expectations. While complacency is often a result of over-confidence, low expectations often arises because businesses lack confidence in their ability to change.

Learn More About Lean Leadership

Read Our Lean Culture Series of Blogs

Overcoming Four Big Barriers to a Lean Culture Part 2: Beating Low Expectations

Overcoming Four Big Barriers to a Lean Culture Part 3: Overcoming Learned Helplessness

Overcoming Four Big Barriers to a Lean Culture Part 4: Stopping Passive Acceptance

What Does Complacency Mean?

Complacency is when people become too comfortable with the way things are and don’t try to make them better. When people become complacent in the workplace, they gain some sense of security in their work and even take dangerous shortcuts to complete tasks. They fail to perform as well as they did when they first began. They also become unaware of their performance deficiencies.

Complacency is a critical problem in big industries like healthcare and construction. Employees and teams in every industry should remain vigilant and carefully observe workplace hazards at all times and to the best of their abilities.

An Example of Complacency

Complacency can happen because of success or lack of it. For example, if employees are highly successful in their position and the employer recognizes it, they may become complacent. They may feel like they’ve reached their limit and fail to realize they’re no longer growing. Their vision for the future gets fuzzy.

Stagnation can also lead to complacency. For example, employees may feel discouraged if they cannot achieve their goals within a given timeframe. They might think that the best thing is to stop trying or even not speak in meetings anymore. Eventually, they may convince themselves they’re not good enough and give up altogether. In both scenarios, complacency prevents personal and professional growth.

Signs of Complacency at Work

It’s essential to recognize when complacency sets in to address and change the behavior before it wreaks havoc. Some signs to look out for include:

- Shortcuts in completing tasks

- Less thought accompanies actions

- Loss of passion in work

- Disengagement

- Lack of investment in self and others

- Disinterest in promotions and opportunities

- Minimal or lack of initiative

- Frequent mistakes

- Carelessness and neglecting tasks

Complacency can lead to loss of trust, productivity, creativity, and loyalty. The management can take steps to improve employee behavior and attitude to reduce complacency. Learn more here.