Lean Manufacturing and its Lean Tools has evolved from its beginnings at Toyota into a system used by businesses around the world.

Lean Manufacturing has brought about a number of standard tools and systems you can use across businesses and industries without much modification.

Below we will talk about the different Lean tools at your disposal when thinking about your Continuous Improvement journey.

1: Practical 5S Systems

Practical 5S is a Workplace organisation tool that standardises a work area by:

- Sorting Out – Leaving only what is needed for the process

- Set In Order – Arranging in the way you need it

- Shine + Check – Keep it clean and simple

- Standardise – Write the standards and share them

- Sustain – Audit, inspect and improve the current standard – repeat

2: A3 Plans

An A3 plan is simply a business plan or project plan expressed on a single A3 sheet of paper.

A3 plans are used for summarising and explaining the strategy, presenting projects and solving problems. By limiting the format to a single A3 sheet of paper and applying rules around layout A3 plans ensure that the essential information is communicated in a clear and concise fashion.

3: Andon Lights

Andon lights refer to a system that provides notification to request support. This is typically leaders, maintenance, and operators of a quality or process. It works when an issue is found at a process, the team member has the ability to immediately notify support staff so that the problem can be reacted to by assigning people within a defined response time.

In manufacturing, it allows a worker to stop production when a problem is found and immediately call for assistance. This can be extended to an office process, where raising an Andon flag means that the process does not go on to the next step until the issue is resolved.

The Andon can be triggered manually or automatically by using push button, pull cord or even flags. The common reasons for activating the Andon can be part shortages, defect created or found, tool/machine malfunction, or the existence of a safety problem.

4: Continuous Flow

One element of a Just In Time system is continuous flow, where the production work in progress moves smoothly between work stages with little (or no) inventory buffers between each step. Understanding Flow; how parts move along the processes, between each workstation and what this looks like across the minute, hours, shift, day, week and month.

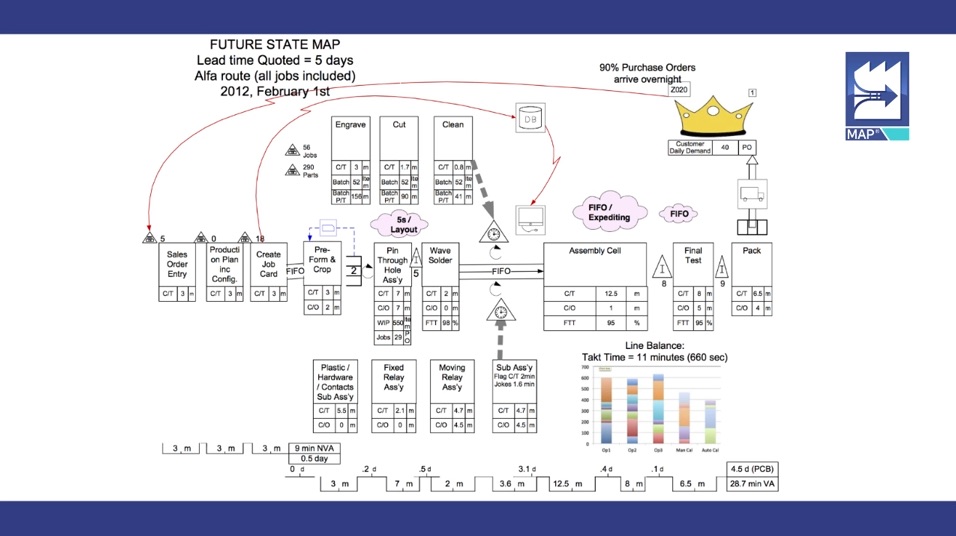

The future state value stream map has provided a vision for what the production flow will look like, defining which parts of the overall production process can flow easily, which parts need direction and which sections need the highest level of control.

5: Kaizen (Change For the Better)/Continuous Improvement

Applied to any organisation, Kaizen implies continuing improvement involving everyone. It usually refers to continuous small step improvements over a sustained period of time. Kaizen usually happens at the “Gemba” or workplace.

It is the Continuous Improvement of your entire value stream for individual or collections of processes that are the total sum of your business. Kaizen at its core is a way of thinking/mindset for improving your business, people, and process.

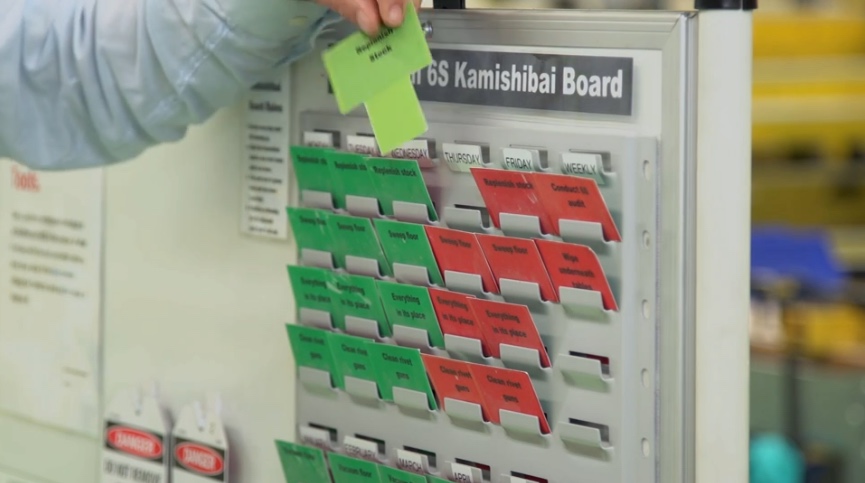

6: Kamishibai Boards (Red Green Task Board)

A system whereby coloured “tee cards” are used to represent routine tasks in the workplace. In the typical application, the tags are printed red on one side and green on the other.

They are then flipped from red to green as tasks are completed. Kamishibai Boards can be used in a variety of situations from the factory floor to daily, weekly and monthly admin tasks in the office.

7: Kanban Systems

A process to signal the need for work, either for Production to make something or stores, or supplier, to supply something. For Kanban the signal is a physical indicator – it may be a card, an empty box or a returned trolley.

Implementing a Kanban system will highlight any problems in your production system. Setting stock levels and reorder lead times will test your initial parts analysis and production data. Audit the system regularly to check all Kanbans are present and they are where they should be.

8: Overall Equipment Effectiveness (OEE)

The origin of OEE is from the Japan Institute of Plant Maintenance and is a key element of the common TPM movement. OEE is a performance measure commonly used to monitor successful improvements to a process/area/machine. OEE is designed to indicate how effectively a manufacturing operation is utilised and is mostly applied to critical or constrained processes.

OEE can at times be a complicated metric to understand as it is derived from three individual calculated components. The components of OEE are: Availability, Performance, and Quality.

To calculate an OEE for a single machine first you need to know your Availability, Performance, and Quality.

• A = Represents the percentage of scheduled time that the operation is available to operate. Often referred to as Uptime.

• P = The speed at which the machine runs as a percentage of its designed speed.

• Q = The Good Units produced as a percentage of the Total Units Started.

OEE= (AxPxQ)

9: Plan Do Check Act/Adjust (PDCA)

Plan, Do, Check, Act or Plan, Do, Check, Adjust is an iterative four-step management method used for the control and continuous improvement of processes and products. At its core it is a problem-solving methodology.

PLAN

This is where you take the overall situation and determine the steps needed to solve the problem. You must define SMART metrics (simple, measurable, achievable, reasonable & trackable) if you want your plan to succeed.

DO

This is when a solution is devised and is implemented.

There may be a mini PDCA cycle with each implementation step; planning what we are going to do, doing it, checking that section and adjusting, before moving onto the next big step.

CHECK

Just because you have put a new system into place doesn’t mean you have finished. You must check your implementation is effective. This is where our SMART metrics help.

If we can’t measure the outcome, then how do we know we have done the right thing? Alternatively, you may have solved one problem but not the one that needed solving.

ACT/ADJUST

Now we compare our checking outcomes against our plan.

If we have achieved the desired results, we document and standardise the process. If our plan hasn’t been achieved, we repeat the process.

Investigate what didn’t work, create a new plan, implement and check how it went this time.

10: Poke Yoke (Error Proofing)

Methods that prevent or detect defects in products.

Error Proofing is the use of any automatic device or method that either makes it impossible for an error to occur or makes the error immediately obvious once it has occurred. It is a common process analysis tool.

11: Total Productive Maintenance (TPM)

Total Productive Maintenance is one of the more advanced Lean Enterprise tools and once Production flow, set up reduction and good housekeeping are in use, it becomes important to keep your machine uptime at it’s best. Running closely in parallel with 5S, TPM is the process where the operator becomes involved with the regular, daily maintenance of their machine.

The targeted machine needs to be thoroughly cleaned and any maintenance issues fixed; the aim is to return the machine to a brand-new condition.

12: Value Stream Mapping

Value Stream Mapping is a powerful Lean technique used to document, analyse and improve information flows or materials required service for a customer. Specifically, a “current state” value stream maps identifies the value and waste in a process flow enabling the development of a “future state map” to eliminate that waste. Toyota created this tool calling it a Material & Information Flow Chart.

Where Do You Begin?

Knowing where to start your Continuous Improvement journey can help you decide which tools you want to implement first.

It can be quite difficult to understand your position but here at TXM, we can help you understand your position and pick the right tools to use in your business.